Advanced Risk Assessment for Quality Risk Management

Move beyond compliance, drive data consistency and improve efficiency.

Move beyond compliance, drive data consistency and improve efficiency.

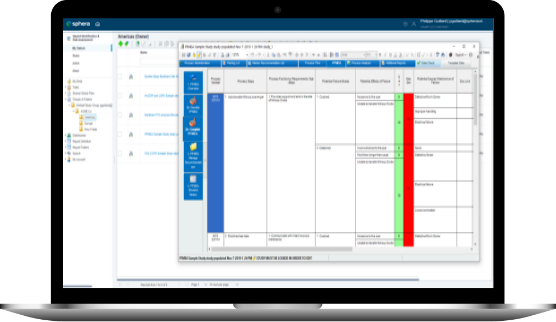

Sphera’s centralized Quality Risk Management software enables organizations to standardize their recording of risk assessment data, while ensuring proper controls are in place. Through configurable templates for methodologies and workflows, capabilities for risk data management, central knowledge repositories and a common risk language, companies can ensure compliance and be better equipped to manage risk proactively.

Teams will immediately benefit from using a shared solution to approve maintenance work, with a comprehensive breakdown of scheduled operational activities and inspection-related tasks. Businesses can consistently deliver high quality, reliable products faster, safer and more efficiently.

Eighty percent of quality issues are repeated events. To break out of these problem cycles, manufacturers must ensure that their quality management processes are consistent. Sphera’s risk templates promote standardization through a common risk language and the flexibility to easily link and share information. Companies can efficiently perform comprehensive quality risk assessments and accelerate productivity.

Advanced Risk Assessment for Quality Risk offers a configurable framework for risk assessment methodologies including Failure Mode and Effects Analysis (FMEA), Process Hazard Analysis (PHA), Layer of Protection Analysis (LOPA), Hazard and Operability studies (HAZOP) and Security and Vulnerability Analysis (SVA).

Quality issues can be disproportionately expensive and can damage your reputation, leading to customer loss. Sphera’s Quality Risk Management software helps companies comply with various quality standards. Users can assign roles, such as risk assessment facilitators, owners, editors and readers. This allows teams to determine traceability and control reliability. Real-time risk distribution and risk dashboards allow reporting on performance. An offline–access feature allows companies to keep their assets safe and productive where there is no internet connectivity.

Companies report 40% to 60% reduction in time and effort for quality risk management by leveraging standardized solutions such as Sphera Advanced Risk Assessment. Using predefined knowledge-based repositories avoids duplication of risk data creation. Advanced Risk Assessment also links critical quality information metrics across decentralized design and manufacturing processes and throughout complex supply chains. With standardized capabilities and processes, proactive risk management becomes a reality.

Advanced Risk Assessment for Quality Risk allows companies to connect data libraries or repositories, supports incident investigation and reduces the resources needed for reporting. Generating ad hoc reports filtered by location, methodology or keywords in minutes, rather than hours, provides tremendous cost savings.

Improved visibility helps keep teams safe and strengthens quality risk management. Sphera Advanced Risk Assessment for Quality Risk enables proactive risk mitigation by providing the information needed for making sound risk-based decisions and enabling next-level safety performance.

Benefit from the unique combination of software, data and expertise to meet all your sustainability and ESG needs.

Identify system conditions through Process Hazard Analysis (PHA) software supported by Hazard and Operability Studies (HAZOP) and “what if” methodologies, Layers of Protection Analysis (LOPA) and Bowtie tools.

Help prevent attacks by finding vulnerabilities, creating actions, tracking results and alerting key stakeholders.

Minimize risk exposure with Sphera’s industry-leading PHA and HAZOP software and services.

Learn more about what SpheraCloud Advanced Risk Assessment software can do to mitigate risk