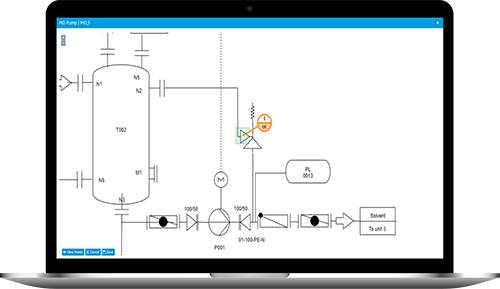

Piping & Instrumentation Diagram (P&ID) Software

Plan and manage isolations with greater safety and efficiency.

Plan and manage isolations with greater safety and efficiency.

Isolation activities, such as removing hydrocarbon from pipes, tanks, vessels and mechanical equipment, require careful planning and management. Bring a greater degree of safety and efficiency to these tasks with Sphera’s Interactive P&ID software.

Quickly and easily search P&IDs, isolation points and equipment, and visually build isolation plans. Sphera’s P&ID software gives you a consolidated view across departments and captures isolation conditions – features that make planning and managing job tasks easier. It ensures that critical isolation information is available to Operations, helping them make sound business decisions that keep people and work sites safe.

Your teams can view the real-time operational status of the asset and identify sources of operational risk and points for control and shutdown. With capabilities like these, it’s easier to adhere to regulatory requirements.

Sphera’s Interactive P&ID software provides quick access to engineering documentation. It lets users upload their PDF schematics and mark up the electronic document with actions, rules, and isolation points. The data is automatically carried into the integrated isolation planning process for full visibility.

The software systematically captures the Management of Change process, promoting continuous improvement in the quality of the P&ID and eliminating rework by automating plans. Streamlined isolation planning with continuous improvement in P&ID quality – who wouldn’t want that?

Sphera’s software makes your isolation planning more efficient by giving you quick access to engineering documentation and interactive capabilities for marking up P&IDs. Operators can also access the relevant P&IDs based on any piece of equipment and reuse previous plans – no need to start from scratch!

Our interactive solution lets Engineering, Maintenance and Operations collaborate on isolation planning and provides operational feedback in a simple, efficient, and intuitive way. These efficiencies deliver real impact by boosting productivity, lowering costs, and keeping the plant and work teams safe.

Benefit from purpose-built solutions with a seamless connection.

Shift the management of activities from permits to real-time, systemwide control. Strengthen compliance and the work permission process by integrating information from permits, risk assessments and isolations. Ensure safety with Lockout/Tagout (LOTO) procedures.

Use a dynamic process safety barrier model to automatically map all performance deviations, hazardous activities, abnormal conditions, human and sensor-derived inputs.

Improve the management of interdependent risks with permitted and operational activities through visualization.

Move fast by ensuring access to response plan information as events unfold, which allows teams to quickly assess the situation and respond appropriately.

Gain insight before a shift, including what happened, current events and predictions for upcoming shift periods.

Identify system conditions through Process Hazard Analysis (PHA) software supported by Hazard and Operability Studies (HAZOP) and “what if” methodologies, Layer of Protection Analysis (LOPA) and Bowtie tools.

Learn more about how Sphera’s Control of Work system helps you take full control of your work activities and operational risk.