Manufacturers of high-volume, high-value products know the consequential loss of downtime as a result of maintenance execution in terms of safety, customer satisfaction, and demand. The combination of simultaneously occurring factors on the ground impacts production, quality and safety. And while there are a lot of data points coming from various management systems and inspection databases – and even paper-based work permits and isolations (LOTO) management systems – a lack of insights makes it challenging to ensure safe and effective operations.

![]()

Achieving breakthrough performance requires a bold, enterprisewide approach to drive real value that shapes operating models. It means reducing data silos and improving work controls with visibility of all risks and activities – enabling operations and maintenance teams to act decisively.

Turning the hype into reality

Sphera’s technology helps industrial and process manufacturers create innovative solutions to enable process efficiencies that drive profitable, sustainable operating models.

Our Control of Work software provides the first integrated, real-time view of an asset’s operational reality with a radically different, far more effective way to visualize and manage work activities and risk. It connects people and helps close-the-loop between operations, maintenance, engineering, EHS&S, and other functions – and brings together disparate data from systems, sensors, and human-derived activities – delivering meaningful, actionable analytics and insights across the organization.

![]()

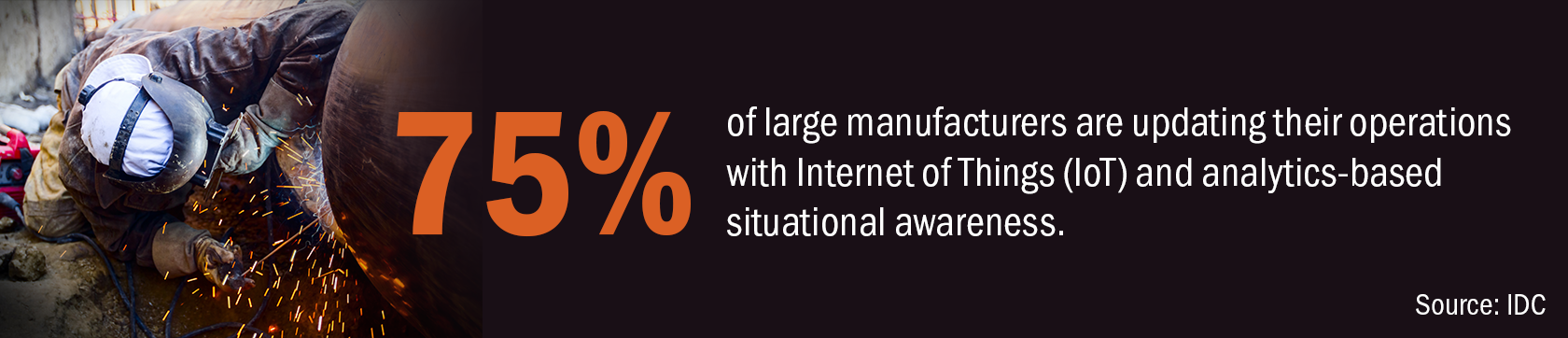

Sphera delivers a real-time, digital replica of the asset that simulates the operational reality. The ORM Digital Twin technology helps manufacturers know what’s happening, when it’s happening, where it’s happening, and what’s driving risk. Now unprecedented situational awareness serves as the basis for cumulative and predictive risk and operations management.

Finally, manufacturers have the tools they need to manage activities and risks in a routine, joined-up way. A common view of risk enables everyone to be better prepared, better informed, better connected so they can make better, more informed decisions.

Are you ready to drive value creation with industry 4.0 technologies that transform your organization’s operational risk management (ORM) and Control of Work? Contact us.

For more information, contact us using the form below.