Not all content is created equal.

When you’re navigating the complexities of global chemical regulations, the right combination of technology and managed regulatory content is critical to maintaining compliance. With Sphera’s authoring solutions, industry-leading content is at your fingertips so you can comply with confidence.

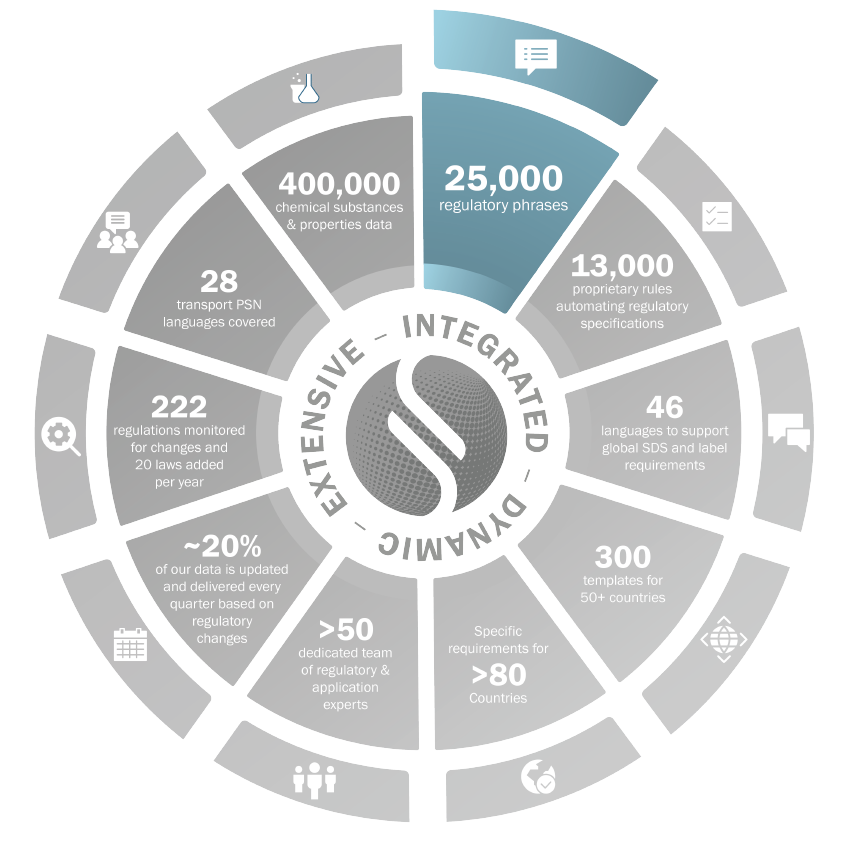

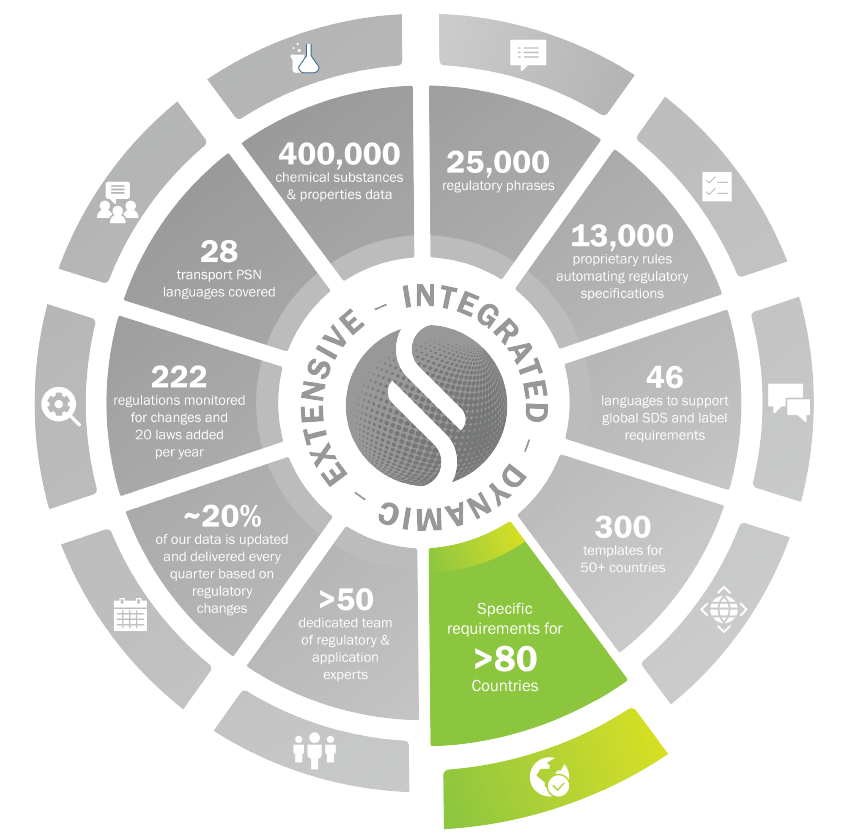

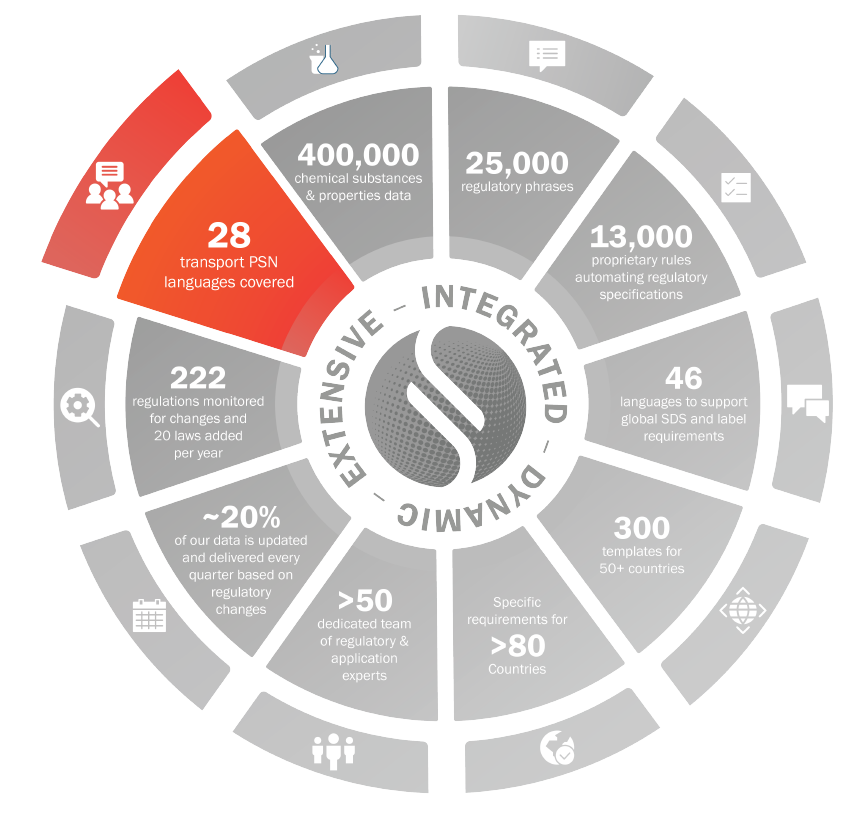

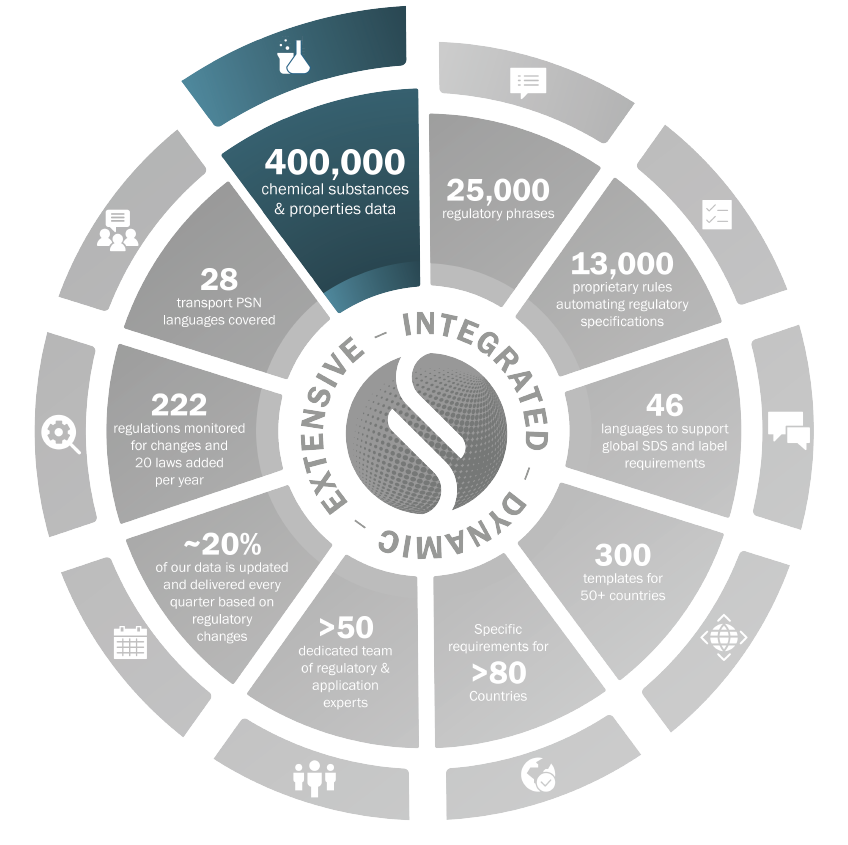

Phrases

Labeling phrases from primary regulatory sources

Non-regulatory phrases translated and peer reviewed by domain experts

Exposure Scenarios phrases from ESCOM standard phrase Catalogue

25,000+ phrases for authoring

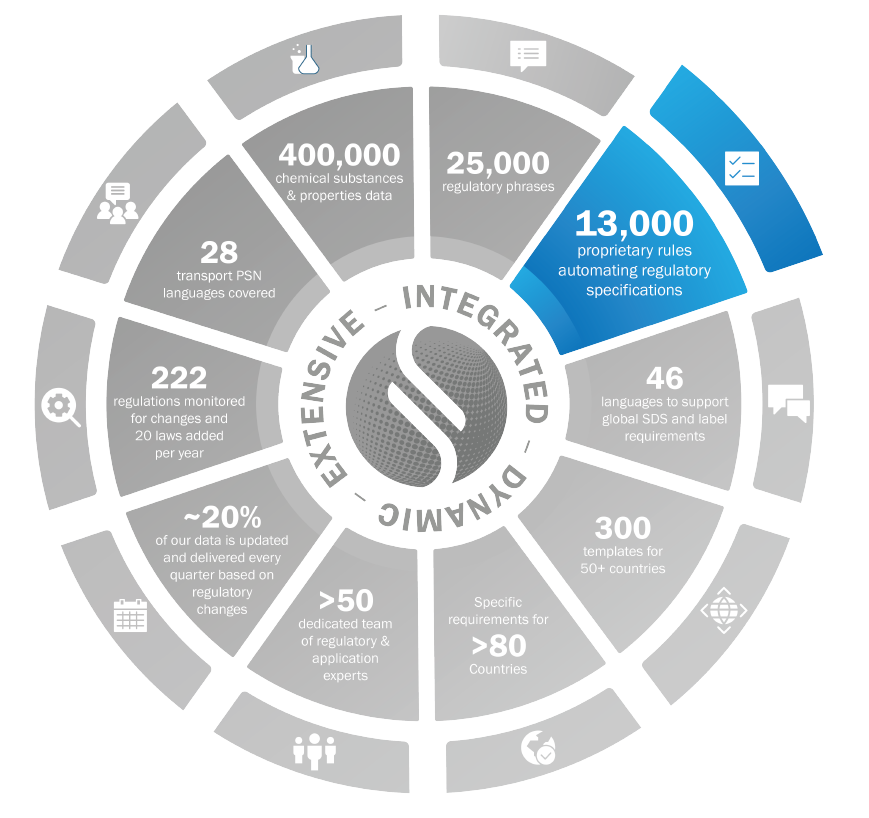

Rules

Audits provide traceability of the inputs considered for supporting an output

Open source grants endless capabilities in tailoring existing or creating new rules

Fast execution enabling the authoring of a coherent and compliant SDS in seconds

13,000+ document authoring

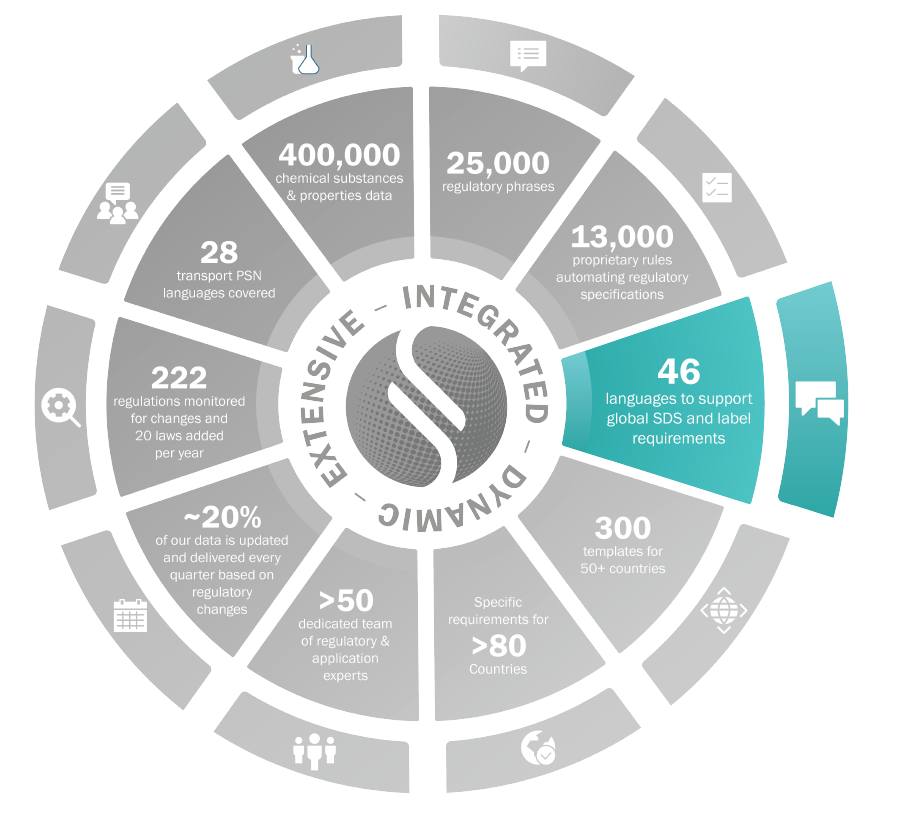

Languages

Translated chemical names provided for more than 50,000 substances

Supports double-byte character sets (Chinese, Japanese, Korean), and right to left languages (Hebrew, Arabic…)

American and European dialects of English, Spanish, French and Portuguese

46 languages translated

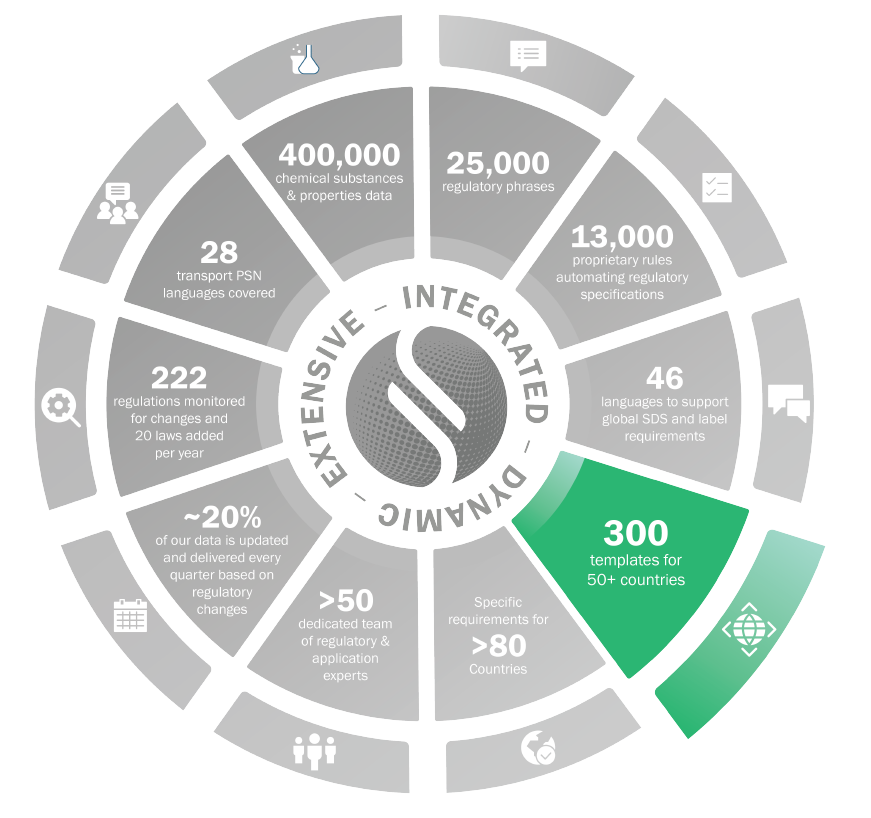

Templates

Template editor for users to tailor existing documents, or create their own (Reports, Product Declarations, Workplace Safety Cards…)

SDS and label templates designed and maintained to comply with country specific regulations

300+ templates provided in the solution

Countries

Occupational Exposures Limits for more than 50 countries and all member states of the European Union

GHS Specific implementation for more than 30 jurisdictions, and expandable with GHS by design

80+ requirements made for countries

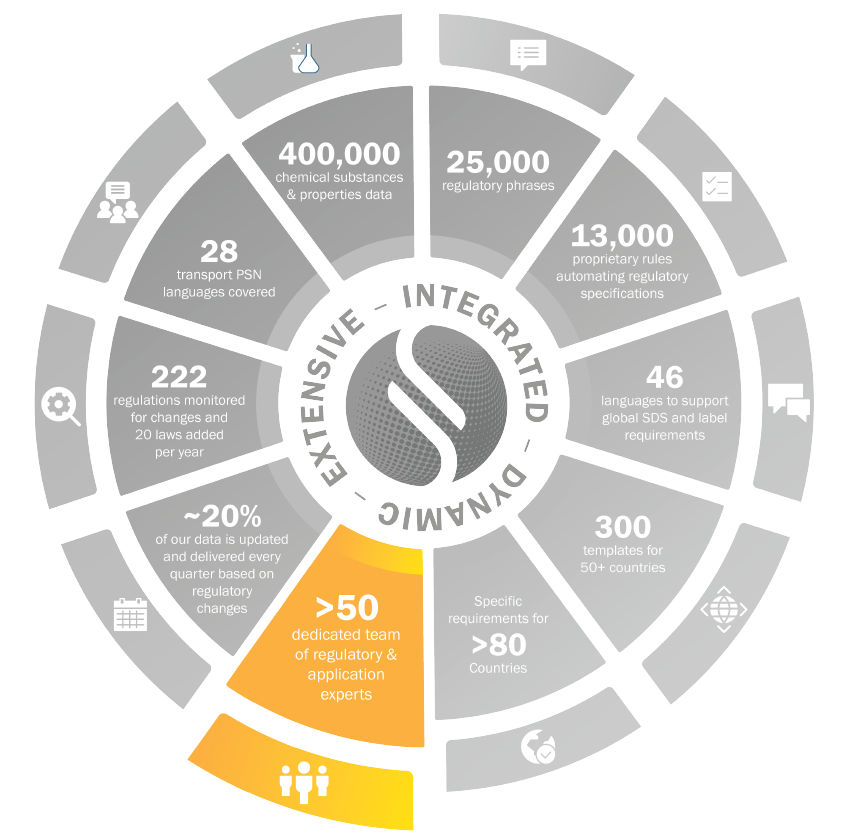

Team

50 full time employees dedicated to the maintenance, improvement and support of managed regulatory content with customers engaged during the design, development and beta test cycles

Regulatory experts, programmers, toxicologists, authors, customer service, product managers, project managers, maintaining, improving and supporting our offerings

50 full time employees

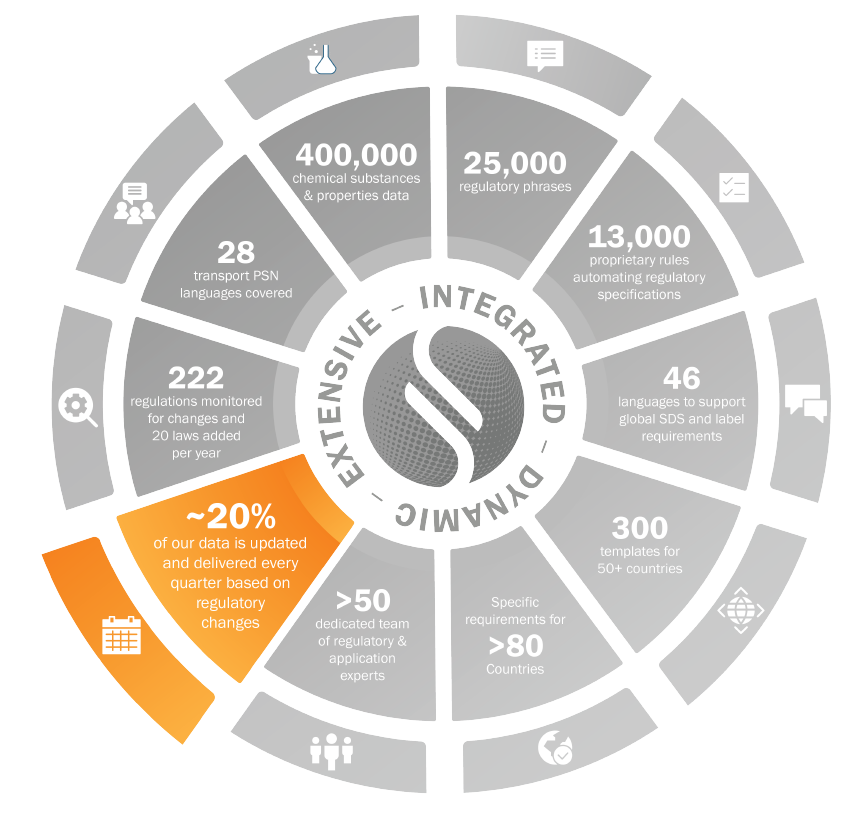

Monitoring

Communication for important regulatory changes

Changed lists are updated and delivered, thus ensuring continuous compliance

Manual and automated monitoring. Interaction with government agencies

20% updated and delivered quarterly

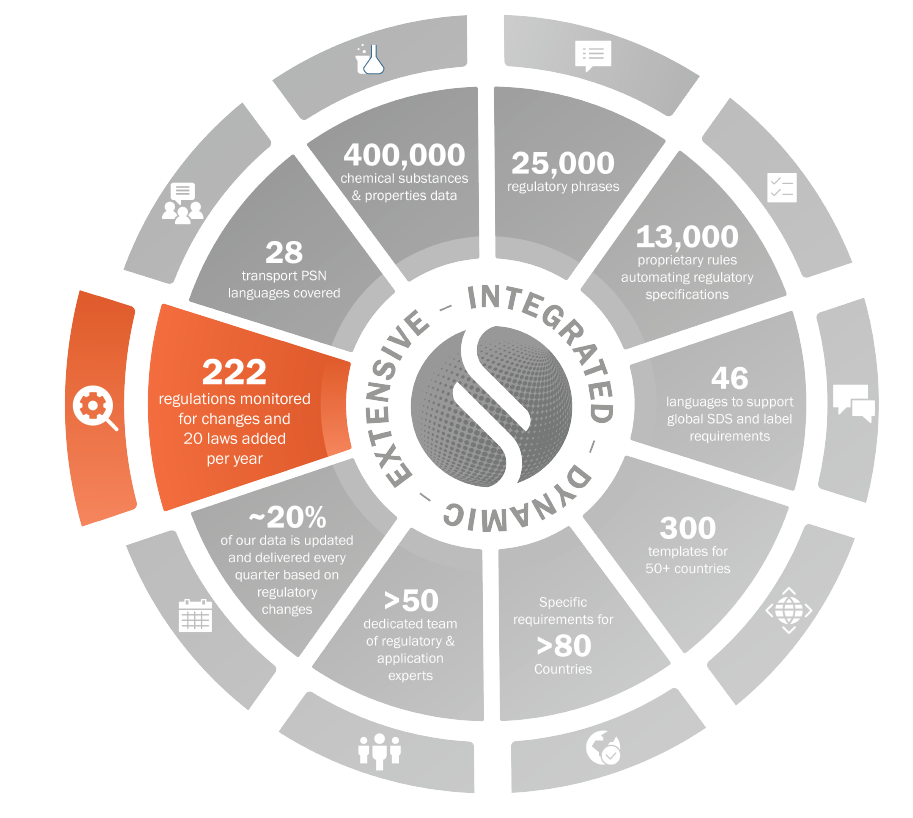

Regulations

Hazard communication

- Classification of substances and mixtures

- “Verbiage” (first-aid, handling, storage)

Industry Specific

- Calculation of VOC net content in mixtures

- CEPE Guidelines (Paints & coatings)

- IFRA Certificates (Flavors and fragrances)

Chemical control

- National Inventory lists

- Bans/restrictions

222 regulations monitored

Transport

Automated transport classification for mixtures, authoring section 14 of an SDS

Specific coverage for IATA, IMDG, DOT, TDG, ADG, NOM Standards etc…

Translated Proper Shipping Names

28 PSN languages covered

Substance Data

Data from registered substances as per REACH (ECHA Source)

Toxicity Data from RTECS, Ecotoxicity Data from EPA AQUIRE

All substances from all National Inventories. Sphera Experts associate substances to Group Definitions

400,000+ chemical substances & properties data

Related Content

Engage with our robust Product Stewardship content library.

Taking Total Control: 4 Reasons Your Business Needs Comprehensive Product Stewardship

Episode 41: This Podcast Is About Control, Total Control

.

EU Poison Centre Notification (PCN) E-Book

.

Ready to learn more?

Tell us how we can help.