Isolation Management Software

Achieve greater safety and efficiency in your energy isolation activities.

Achieve greater safety and efficiency in your energy isolation activities.

Effective isolation management is not possible without a comprehensive view of your energy sources. Your work crews must be aware of all hotspots and hazardous energy sources and conduits to prevent the uncontrolled or unplanned release of energy.

Your teams also need real-time insights for effective preventative and risk-reduction measures. Sphera’s software provides these insights to help your teams safely and reliably isolate machines and equipment from uncontrolled energy.

Improve isolation discipline and ensure executive, maintenance and contractor adherence to policies, from beginning to end.

With Sphera’s solution, users can quickly identify the risks of potentially hazardous energy sources. They can also track the status of each isolation point, monitor the integrity of critical valves, and access work, authorization and performance history. This helps teams manage isolation procedures when preparing the plant for safe work, testing and the return to normal operations.

Create safe procedures for energy deactivation with our solution’s framework and workflow-enabled processes. These features also help you eliminate rework, improve learning and reduce duplicate entry by copying existing, approved isolation plans.

Our solution automatically notifies you if your isolations don’t meet standards or if potential conflicts exist. With this enhanced visibility, you can improve productivity and reduce bottlenecks.

For a safe production system and working environment, Operations must respect high isolation standards, rigorous control measures and process safety regulations. Work crews must be aware of hotspots and know how to control hazardous energy in systems, pipes, tanks, wells, vessels and mechanical equipment to prevent a loss of containment.

Sphera’s solution gives you a comprehensive view of energy sources and pathways, as well as real-time insights, to help you reduce the risk to your employees and assets.

Benefit from purpose-built solutions with a seamless connection.

Shift the management of activities from permits to real-time, system-wide control. Strengthen compliance and the work permission process by integrating information from permits, risk assessments and isolations. Ensure safety with Lockout/Tagout (LOTO) procedures.

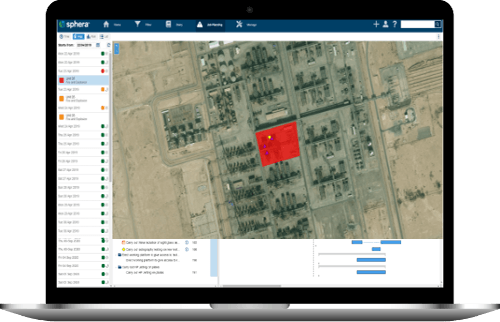

Improve the management of interdependent risks with permitted and operational activities through visualization.

Gain insight before a shift, including what happened, current events and predictions for upcoming shift periods.

Use a dynamic process safety barrier model to automatically map all performance deviations, hazardous activities, abnormal conditions, human and sensor-derived inputs. Simulate in real-time the Major Accident Hazard (MAH) risk impact of work activities, risks and process safety-critical equipment in each area of your asset.

Learn more about how Sphera’s Control of Work system helps you take full control of your work activities and operational risk.