Danone is a global leader in food and beverage, employing approximately 90,000 people worldwide with headquarters in Paris, France. Operating complex manufacturing environments across multiple regions, Danone places strong emphasis on protecting employees, contractors and assets while ensuring consistent regulatory compliance and operational excellence.

Challenges

As Danone continued to expand and evolve its global operations, it faced growing challenges in managing health, safety and high-risk work activities consistently across sites.

Key challenges included:

1

Fragmented and inconsistent safety processes and data across regions, inconsistent discipline in execution, and difficulty coordinating simultaneous operations.

2

Heavy reliance on paper-based and manual systems leading to high administrative workloads.

3

Limited visibility into contractor activity, work status, and risk exposure, as well as safety data not enabling proactive insights.

4

Recurring incidents linked to high-risk activities such as LOTO, confined space entry, and equipment isolation.

Danone needed a scalable digital solution that could standardize safety management globally while improving transparency, engagement and accountability.

Danone selected Sphera’s Health and Safety Management and Control of Work solutions to support their global digital safety transformation roadmap, adopting built-for-purpose software to streamline and strengthen their safety program, accelerate digitalization and connect safety management, risk identification and the safe execution of work.

Solution

Danone implemented the SpheraCloud software platform to future-proof their EHS program. The initial rollout included incident management and action software, with audits and contractor management as subsequent steps. The intuitive and user-friendly SpheraCloud First Report portal ensures all employees, including contractors, can report incidents, near misses and safety observations. This engagement is critical for workplace safety, to act quickly on incidents with corrective actions and remediations but it also helps to prevent future events from happening by providing valuable data through near-misses and observations. In order to improve the collected health and safety data, Danone has set up specific workflows to evaluate and ensure data quality.

Danone’s comprehensive contractor management program is designed to ensure the highest safety standards by treating contractors as partners. This program begins with a thorough contractor selection process that evaluates health and safety policies and anticipates potential risks. Contractors are integrated into Danone’s safety processes, gaining access to essential tools like incident reporting systems. Regular reviews with contractors help address challenges and assess both health and safety performance. Risk identification is conducted using a control of work tool tailored to specific contractor activities. A visual dashboard tracks performance trends, identifies risk hotspots, and outlines necessary actions. Additionally, specific contractor assessments are carried out through Danone’s health and safety audit program to ensure compliance across all sites.

Results

By using Health and Safety Management and Control of Work as part of the SpheraCloud platform, Danone has achieved both quantifiable safety outcomes and operational efficiency gains.

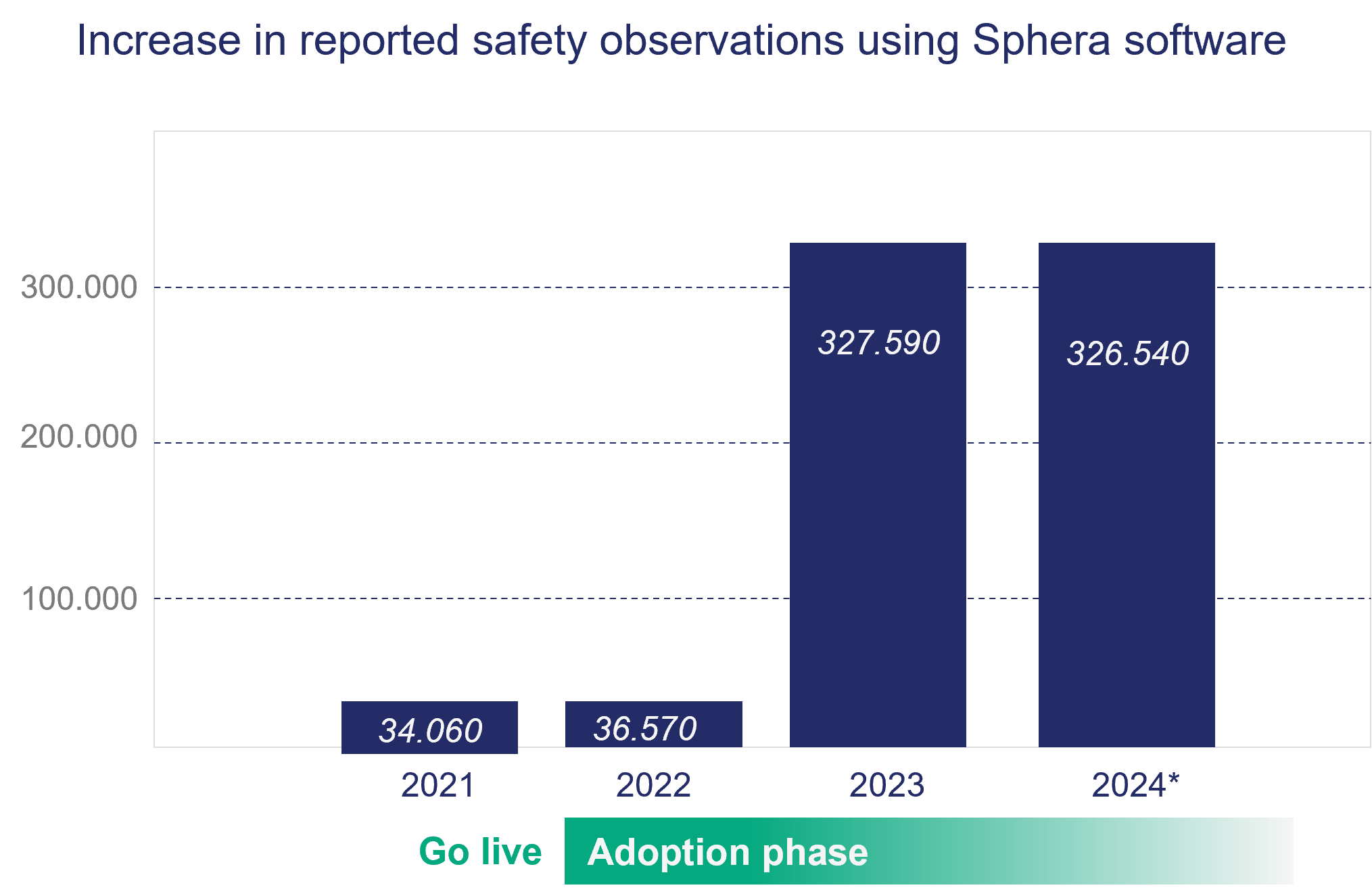

796% increase in reported safety observations, significantly improving frontline engagement and visibility of risks

21% reduction in frequency rate between 2021 and 2024, demonstrating meaningful improvement in safety performance

Improved quality and consistency of safety data across regions

While long-term metrics are still being collected for the Control of Work solution, Danone has already realized clear benefits from its implementation:

- Increased compliance with permit-to-work requirements, automated controls preventing unauthorized approvals, and greater confidence in the proper application of hazards and controls.

- Improved efficiency and productivity through time saving for permits.

- Real-time operational visibility across sites.

Danone continues to expand its use of Sphera’s platform, leveraging safety insights and control of work discipline to further improve analytics, consistency and proactive risk management. The safety solutions provide a strong foundation for continuous improvement and long-term safety excellence across Danone’s global operations.

This connected approach has strengthened Danone’s safety culture, improved contractor oversight and established a scalable global model that can be rolled out across additional sites and regions.

What made this happen?

Health and Safety Management Software

Health and Safety Management provides a centralized system to capture and manage incidents, near misses and observations while standardizing investigations and corrective actions. It improves data quality, reporting consistency and provides insights into trends, recurring risks and leading indicators. By strengthening contractor oversight and enabling data-driven decision-making, the solution fosters a strong safety culture and engagement at both local and global levels.

Control of Work Software

Control of Work digitalizes and standardizes the management of high-risk activities. Key features include digital Permit to Work processes, structured risk assessments, automated approvals, real-time visibility of permits, and improved coordination of simultaneous activities. By replacing paper-based permits and inconsistent practices, this solution ensures work is planned, reviewed and executed safely, with clear accountability and greater transparency across contractors, assets, and sites.

“Moving from paper to a unified digital solution has given us far better visibility and confidence in how safety processes are applied. We can see what’s happening in real time, ensure the right steps are followed and manage high-risk activities much more effectively.”

— Guillaume Raga, LATAM & Digital HS Director, Danone

CASE STUDIES

Sphera in action

Atlantic Grupa strengthens supply chain resilience and sustainability with Sphera SCRM

Danone: Driving consistent safety performance at global scale

PCF study confirms 54% lower carbon footprint of Republic Services’ recycled plastic flake for sustainable packaging