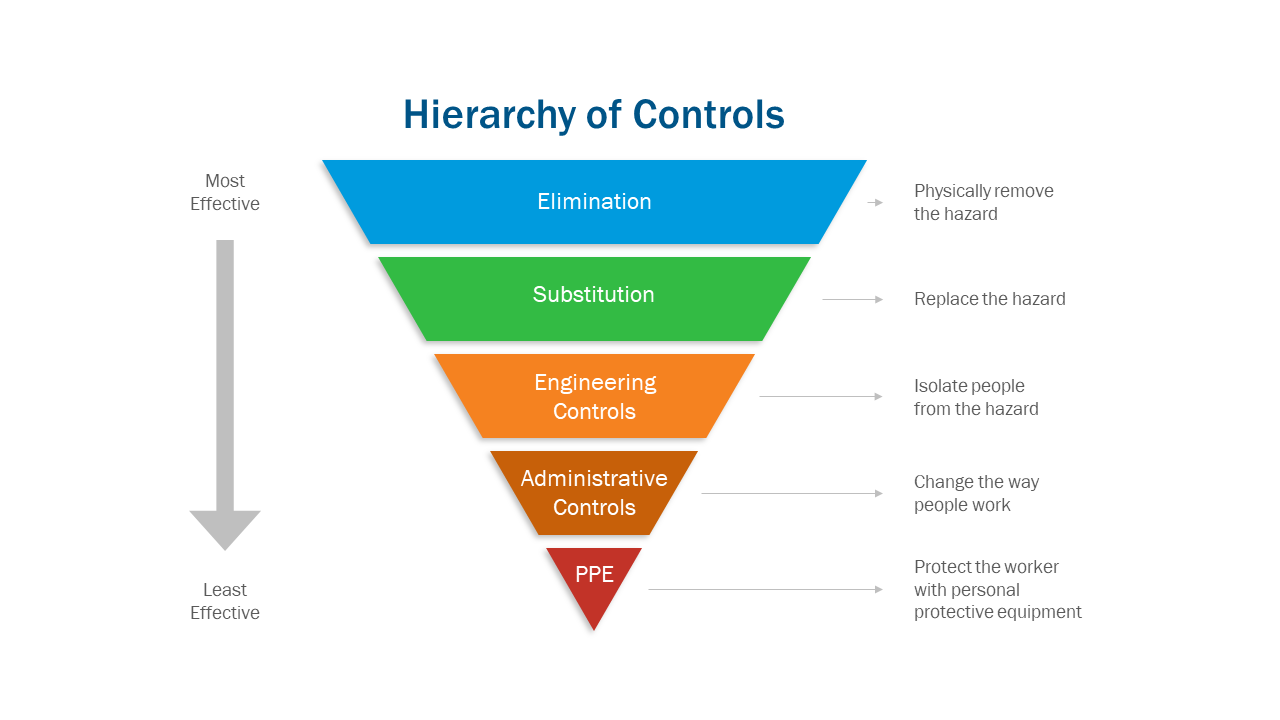

Experienced safety professionals are sure to recognize the inverted pyramid of the hierarchy of controls, a method of identifying and ranking the safeguards used for protecting workers from hazards. Developed in the 1950s by the U.S. National Safety Council and refined by the U.S. Occupational Safety and Health Administration and other safety organizations, the hierarchy of controls helps companies improve workplace safety. Today, this control hierarchy has become more relevant than ever. When applied in combination with digital tools, this hazard-control and risk-management model can be a powerful ally for reducing incidents, increasing uptime and saving lives.

What Is the Hierarchy of Controls?

In highly hazardous industries such as mining and metals, oil and gas or nuclear power generation, controls are measures that reduce risks at various process stages. In this five-layer model, risk control starts with the most effective measures at the broad top of the upside-down triangle. Then it goes down through various layers of control to the least effective measures at the tip.

Without a doubt, the hierarchy of hazard controls saves lives. Why? Hazard elimination, risk reduction and safety procedures are all included in the control framework. Such measures all contribute to incident prevention, and preventing incidents is the best way to save lives.

Source: National Institute for Occupational Safety and Health (NIOSH)

How Many Steps Are There in the Hierarchy of Controls?

The five layers of the hierarchy of controls begin with prevention—in other words, removing the danger. This is always the most effective safety measure, so this is the first step.

- Elimination: Remove the Hazard

In this step, work processes are adjusted to avoid the dangerous process step. For example, in a facility, a pump may be too high to work on from the ground. Typically, a worker would be hoisted up—perhaps to a scaffolding—and wear a harness. Yet the risk of falling still exists. Lowering the pump to ground level would remove this hazard.However, this type of process adjustment may not be feasible, which is why hazards cannot always be removed. Here, digital tools give visibility into operations, logbooks and shift handovers. This helps teams to communicate the status and thought processes of certain hazards on jobs and activities. - Substitution: Replace the Hazard

In the next step, a hazard that cannot be removed is replaced with a less hazardous risk. In oil and gas, for example, sections of pipe are cleaned using high air pressure. Engineers typically put a rupture disc on one end of the pipe, designed to prevent leakage until the pressure rises to a predetermined level. At that point, the rupture disc bursts to avoid damage to equipment from overpressure.The desired level of pressure might be 150 pounds per square inch (psi). However, this would blast out large pieces of debris that could strike workers at high force. The substitution would be to start with 50 psi, which blows out smaller particles of dirt and deposits. When the pressure is increased incrementally, the overall process becomes less hazardous. Here, too, with digital systems, process safety managers can better evaluate hazards for substitution. - Engineering Control: Install Barriers, Controls, Isolations and Safeguards

When risks cannot be removed or replaced, reliability engineers typically put barriers in place to isolate people from the hazard. Physical guardrails or fencing prevent people from walking in hazardous areas. Welders put up fire-retardant blankets.When the use of flammable or explosive chemicals cannot be eliminated, one type of safeguard would be to limit admission to rooms with hazardous chemicals. However, unseen risks can remain. By giving visibility to isolations and barrier management, control of work software for permitting supports engineering controls. - Administrative Control: Change Behavior

Where possible, companies reduce risk by changing the way work is done. Employees and contractors receive safety guidelines, specific information or training on hazardous procedures. Only certified administrators or workers with certain types of equipment have access to dangerous areas. In addition, signals such as warning signs, alarms or flashing lights are used to trigger safe behavior.These lower levels require increasing supervision and participation. Through digitalization, companies can improve situational awareness, human performance and safety culture. Technology can be used to monitor facility risk and safety status in real time and alert operators should risk arise. And, with mobile tracking, supervisors can tell if tasks were performed in the right locations. - Personal Protective Equipment (PPE): Protect Workers

When the risk of injury or harm remains after all other control measures have been implemented, workers use PPE as a last line of defense. Wearables are often designed for specific hazards at a site, such as flame-resistant clothing, hard hats, gloves, glasses, ear protection and safety shoes. Job-specific PPE can include respirators, certain kinds of gloves or overalls.PPE does not control the hazard, but rather, lowers the employee’s risk of injury. With a digitalized system, operators can more consistently alert workers and contractors to risks and danger. Relevant safety reminders—for example, “Wear a hard hat with a flashlight”—can be transmitted at exactly the right time.

Benefits of Digitalizing Control Hierarchy Processes

From start to finish, digitalizing hazard-control processes results in efficiency and productivity gains. Companies develop better processes and controls and enjoy benefits including:

- Standardization. Safety protocols, control systems and hazard management are consistent across a site, across facilities or throughout the company. With internet access, data is available everywhere simultaneously and in real time.

- Efficiency. Digital tools offer huge savings in time and effort compared to paper processes. No illegible handwriting. No more filing, searching or trying to recover wet or torn permits.

- Reliability. Process steps must be completed in the same order and can be verified and tracked.

- Uptime. By reducing the risk of incidents, the company suffers less downtime and related costs.

- Savings. As incidents go down, productivity goes up, while a reduction in incidents reduces injuries and fatalities and saves money.

In addition, companies can more efficiently gather statistics on the types of job, hazard areas or equipment used, for example, to run reports and perform audits. Lessons learned help operators understand the most significant challenges and establish which measures work best. This enables them to develop better processes, engineering controls and administrative controls for the future.

Risk Control and Hazard Management Are Key to Safety

The hierarchy of controls helps companies improve workplace safety. From hazard elimination and substitution to engineering and administrative controls, down to PPE, the model for reducing exposures to occupational hazards saves lives and money.

Digitalization makes the five layers of risk control and hazard management more easily accessible. Powerful digital tools such as process safety management software help managers determine the safest level of any job and make it easier for them to apply the corresponding control measures to ensure worker health and safety.