Circular economy refers to a model in which economic growth does not go hand in hand with the exploitation and consumption of natural, non-renewable resources. The aim of a circular economy is the resource-efficient and sustainable use of natural resources, their reuse and recycling within a circulatory system and the prevention of waste.

The implementation of a circular economy should not be in conflict with economic interests.

The latter are served by the fact that in the system of circular economy companies generate an additional value from the materials used and the reduction of procurement risks in the form of material costs, price volatilities and supply bottlenecks. Unlike the linear economy, ecology and economy are not in competition with each other in the circular economy.

Linear Economy and Circular Economy

“Take – Make – Throw away” vs. “Reusing, Repairing, Recycling”. Two conflicting concepts with different impacts on the consumption of resources and pressures on the environment.

How to Measure the Level of Circular Economy

The circularity – also called “material circularity” – is an expression of the compatibility of the model under investigation with the principle of a circular economy.

But how is it possible to scientifically assess to what extent and how effectively companies or products correspond to the circular economy and what progress they make in their development away from the linear economic model towards a circular economy?

Valid information was hard to come by in the past, and the statements in this regard are rather vague and non-binding.

In the “Circularity Indicators” project, the EllenMacArthur Foundation and Granta Design have developed a methodology for capturing the circularity of products and companies based on facts and numbers.

Material Circularity Indicator (MCI)

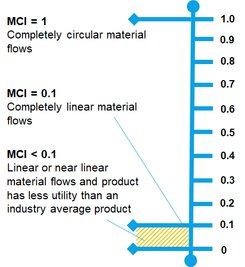

The Material Circularity Indicator (MCI) represents the degree of the material flow’s circulatory on a scale of 0 to 1. The higher the score, the more recyclable or circular the product.

The MCI can be a decision-making tool for product designers and buyers to select materials, use it for reporting or to evaluate companies. The assumption here is that the circularity of a company is made up of the individual material circularities of its products.

Companies that want to improve the sustainability of their products or, at first, decide on their current status often use Life Cycle Assessments (LCA). Here, all incoming and outgoing material and energy flows of a product are recorded over its entire life cycle and on this basis the resulting possible environmental effects are derived.

In order to be able to calculate the results of LCAs, it is common to use dedicated circular economy software tools such as Sphera’s LCA for Experts Software. Circular economy software allows the user to construct detailed models of the life cycle of the product systems they want to examine. There is a great deal of overlap in the data requirements for developing LCA models and for calculating the MCI.

Both require information on mass flows of raw materials and wastes, on whether raw materials are obtained from virgin, recycled or reused sources and on how waste are treated. Taking advantage of this commonality of data, Sphera has developed the LCA for Experts Toolkit. This can be applied to LCA for Experts models and requires making some minor adjustments that then allows the MCI to be calculated alongside conventional LCA results. The LCA for Experts Toolkit lets you apply the power of our scenario analysis features to quickly and conveniently calculate MCI results of different alternatives. This is much faster and more reliable than attempting to calculate the MCI in a spreadsheet. In this form it is unique on the market.

Further Resources on Circular Economy