Sphera’s Standard Modifier Dictionary (SMD) is a consistent, unambiguous classification system and technical dictionary of materials and spare parts for maintenance, repair and operations (MRO).

Created more than 45 years ago, continuously improved and adapted, and with templates for more than 2,500 types of parts, Sphera’s Standard Modifier Dictionary represents the most comprehensive and widely- used cataloguing methodology in the world.

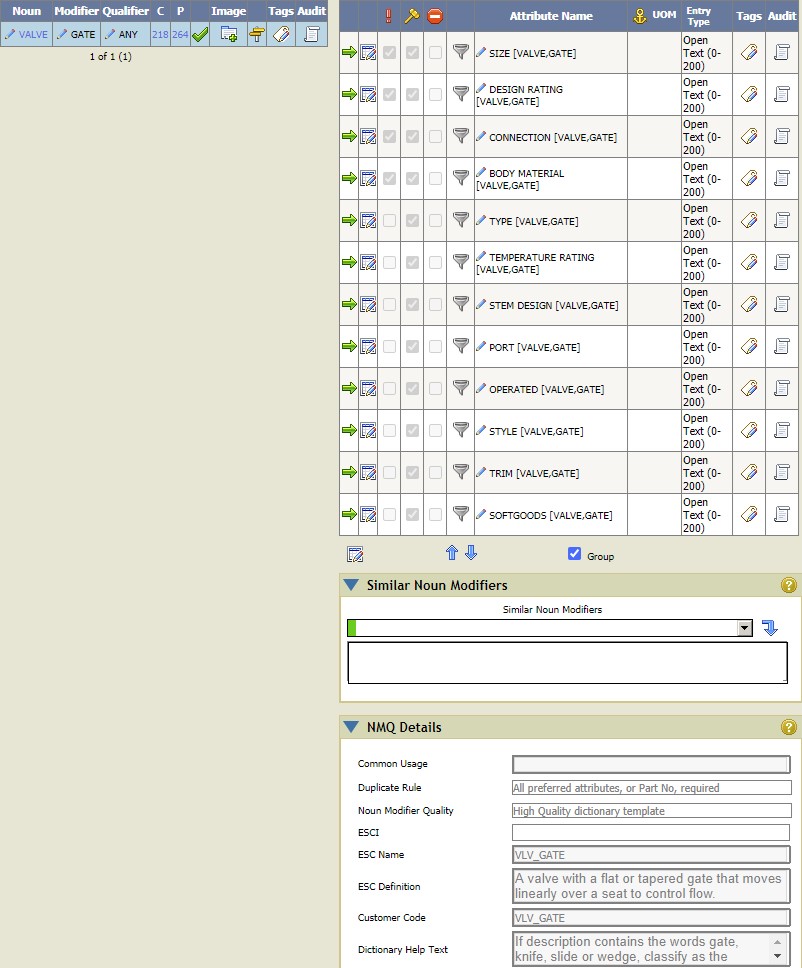

How the Standard Modifier Dictionary Is Structured

Sphera’s SMD consists of a two-tiered classification family of mutually exclusive descriptors and a repeatable set of rules for characterizing parts. There is also an optional third-tier “upper classification” level.

Why the SMD Is Important for Managing Materials and Spare Parts

In many organizations, item descriptions for materials and parts used in maintenance, repair and operations commonly exist as unstructured “free-form” text. Material and spare parts data may have been created by external purchasing organizations or generated by disparate business systems. This results in item descriptions that are inconsistent, incomplete and non-comparable, and often results in duplications of data that represent the same unique item.

Poor specifications can lead to unsearchable databases, inefficient replenishment, duplicates or stock-outs and wasted process-cycle times. In the worst case, inconsistently categorized parts could lead to maintenance delays, equipment failure, production downtime or even catastrophic events such as explosions caused by malfunction from inferior or ill-fitting parts. To help companies maintain reliable, searchable spare parts data and material master data, the application called Finder was developed, and later enhanced into SpheraCloud.

With consistent SMD classifications based on nouns, modifiers and characteristics, enterprises are able to:

- Cleanse item descriptions using industry-proven templates and tools.

- Standardize categorization and things like Units of Measure (UoM) to achieve conformity among descriptions from various manufacturers.

- Enrich descriptions with key attributes that differentiate materials within the same family.

- Normalize descriptions for simple parts searches and parametric searches, to facilitate quick and accurate data queries.

- Optimize information to provide clear and comparable item descriptions.

- Sustain the supply chain needed for maintenance, repair and operations.

Sphera’s SMD may be modified to suite specific customer requirements. For example, it helps companies achieve conformity among disparate enterprise resource planning (ERP) or asset management (EAM) systems, to ensure that the right data is available across the company.

How the Standard Modifier Dictionary Differs from Other Cataloguing Methodologies

As Sphera’s SMD is based on nouns, modifiers, synonyms and characteristics, it represents an improvement over other nonintuitive, number-based classification systems. A consistent, word-based comprehensive materials and spare parts classification system supports functions including sourcing, procurement, inventory management, as well as maintenance, repair and operations. Users can:

- Identify duplicate inventory.

- Avoid false stock-outs.

- Simplify inventory searches.

- Achieve maximum benefits from their ERP/EAM systems.

- Reduce equipment downtime.

With Sphera’s SMD, customers can realize significant savings. Rich, complete, consistent, text-based, human-readable materials and spare parts data (along with codifications) helps make plant maintenance more efficient, resulting in more reliable and productive operations. This comprehensive classification schema helps optimize storerooms and inventory levels, reduce spend and make procurement and sourcing more effective, all of which contribute to greater supply chain resilience.

The Development History and Timeline of Sphera’s Standard Modifier Dictionary

Sphera has developed our SMD over the course of more than 45 years. The guiding philosophy in its creation has been to support the capture of spares and materials data and to provide consistent, information-rich descriptions to support the needs of the users in searching for parts. Here are a few of the key technology and business milestones along the way:

1978 – The company Intermat creates Struxure software along with its Standard Modifier Dictionary, the first-ever dictionary for classifying materials and spare parts in maintenance, repair and operations.

1998 – SparesFinder is founded in the U.K. to market the Virtual Pooled Industry technology, which connects engineering spare parts and materials with end users via the web. Its cloud-based solution, Masterpiece, and the along with Finder and Gatekeeper applications, are designed to help companies maintain accurate, accessible and reliable spare parts data and material master data tools and cataloguing services for supplies needed in maintenance, repair and operations, buys Intermat.

2004 – The company IHS Markit purchases the assets from PSDI, and further develops the Struxure software and the Standard Modifier Dictionary.

2016 – Sphera is created when Genstar Financial acquires assets from IHS, including Struxure and SMD.

2018 – Sphera acquires the company SparesFinder and its cloud-based software. The Standard Modifier Dictionary is enhanced into the updated SpheraCloud Master Data Management for maintenance, repair and operations software, which continues to this day exists today as Version 4.

Sphera’s SMD is currently comprised of approximately 2,800 Noun-Modifier pairs, 1,200 Synonyms, 25,000 Characteristics, 28,000 Definitions and Guideline rules, 29,000 Sample Values and 2,600 Reference Images. As the first and likely the most prolific technical dictionary for maintenance, repair and operations data, Sphera’s SMD is the de facto global standard taxonomy.