Globally, businesses are beginning to realize that there is an urgent need for quick, decisive, and meaningful corporate action when faced with the issue of sustainability. As companies act upon their commitments, they realize the critical role suppliers play in shaping their sustainability story. This, for many, raises the question: How do I engage my suppliers to improve?

Of course, it’s unrealistic to expect all suppliers to meet your sustainability standards immediately. But, over time, lagging performance can result in a risk to your business and reputation if left unaddressed.

Figuring out what to do about your low-performing suppliers can be complex, often resurfacing the age-old debate about striking the correct balance between “carrot” vs. “stick” incentives. So, drawing from our customers’ experiences and current market trends, we’ve compiled our take below.

The Sustainable Supply Chain Journey ─ A Reminder

Before we dive in, it’s important to note where you are at in the supply chain sustainability journey. If you’re wondering what to do about low-performing suppliers or how to drive improvement, you’re in the “action” phase and have probably already accomplished:

- Setting corporate supplier sustainability goals

- Creating corresponding internal sourcing policies

- Mapping your multi-tier supply chain

- Sending self-assessments to gather supplier sustainability data

- Potentially verifying data and followed up with an on-site audit

- Analyzing your data to identify high-risk and low-performing suppliers

If you’re looking for more information about any of these steps, check out the SupplyShift guide to supply chain sustainability. Otherwise, let’s move on to how to handle your low-performing suppliers.

Engage to Reform vs. End Contract

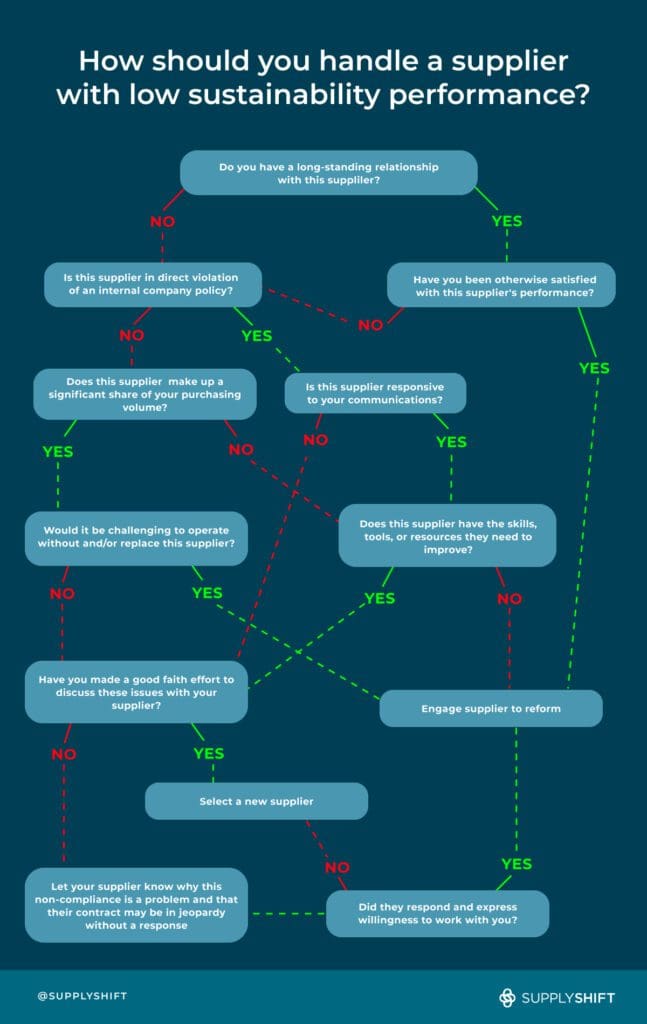

There are two options available to you when suppliers are failing to meet your sustainability criteria: engaging them to reform or selecting a new supplier. However, it’s more complicated in practice. So we’ve highlighted a few factors that you should consider:

- How long have you worked with this supplier? If you’ve both shared a long, positive, and beneficial relationship, avoid punishing this supplier by pulling their contract. Work together to plan for improvement.

- Is this the first time you’ve gathered sustainability data from this supplier? If you’re in the first iteration of your supplier assessment initiative, don’t expect all your suppliers to immediately meet your standards. Conversely, if you’re in year five and haven’t seen any tangible improvement, perhaps it’s time to reevaluate.

- Is your supplier responsive to communications? If your supplier has proven to be a speedy responder and a willing partner, then the chances are they’ll be receptive to adopting your sustainability criteria.

- Does your supplier account for a significant share of purchasing volume? It’s fair to say that the supply disruptions of the past year have reminded us that we need to be realistic. If your supplier provides you with a large share of your goods and consistently performs well (be that speed of delivery or price), it may be wise to avoid suspending their contract based on their sustainability performance alone.

- Has there been a direct violation of compliance? Depending on how serious the violation is, continuing to work with this supplier may pose too big a risk to your business. Be mindful and remain observant; is the violation so severe it requires a suspension, or can this be avoided with reform?

Check out the diagram below for a summary of how to navigate the thought process on how to handle a low-performing supplier.

The Importance of Delivering Value

Keep in mind that your suppliers shouldn’t be shouldering all the burden. If you want them to participate and improve in your initiatives, you need to make the process appealing to them as well. If you’re overwhelming suppliers with data requests without ever providing anything in return, it should be no surprise that they underperform on sustainability. They need incentives.

For example, you have a supplier who’s repeatedly scored low on GHG emissions over the past three years, and you’re weighing whether to terminate their contract. Have you shared their results with them? Showing suppliers where they’re performing compared to their peers is a simple way to deliver value and push for improvement.

Not possessing a foundation of two-way communication, transparency, and added value on both sides increases the risk of making decisions without giving your suppliers a chance to redeem themselves.

Special Considerations for SMEs

Ask yourself, do your suppliers have the knowledge, skills, or resources at their disposal to perform better? SMEs, or smallholders in agricultural supply chains, may struggle with having the right tools for improvement, and, in the majority of supply chains, these SMEs/smallholders form a large share of the network.

Enhancing capacity with these suppliers and supporting them along your journey is paramount. Before you write them off as low sustainability performers, start the conversation to understand what obstacles they face. Ask about:

- Lack of financial resources to improve or participate in a certification scheme

- Lack of knowledge to provide sustainability data, requested calculations, or make necessarychanges

- Poor infrastructure or lack of community development resources

- Any cultural/regulatory differences

If you’d like to see this tactic in action, take a look at Mars’ new Supplier Leadership on Climate Transition (Supplier LoCT) coalition providing its suppliers with tools to develop their own climate action plans and set SBTs. Similarly, Bayer recently committed to empowering 100 million smallholder farmers by making agronomic knowledge, products, public health services, partnerships, and economic opportunities more accessible.

So, when tackling poor performance with SME suppliers, supporting them with resources to lower their barriers should be top of your engagement strategy priority list.

Using the Right Tools

Handling low sustainability performers via relationship management can be time-consuming and feel like a largely qualitative process. However, tools are available that can streamline this process and make it easier to track your progress over time.

A considerable proportion of these tools are referred to as supplier sustainability platforms, and they combine some of the following features:

- Supply chain mapping

- Supplier assessments (standardized or custom)

- Real-time analytics

- Supplier scorecards

- Audit support

- Supplier improvement resources

- Supplier communications/corrective actions portal

Nearly any supplier sustainability platform allows you to track supplier performance annually, but when handling low performers and trying to drive progress, make sure to select a platform with solid supplier engagement tools: centralized communications portal, capacity building resources, built-in recommendations, etc.

This creates a centralized hub for you to oversee the engagement status of each of your suppliers, what action items you’ve assigned to them, and what progress you’re monitoring. Ideally, this information would be consolidated into your existing procurement systems, allowing your sustainability performance to be visualized side by side with factors such as price and quality.

Closing Thoughts ─ Keep the Human Element in Mind

We owe a lot to digitalization and globalization. They’ve allowed our supply chains to become more complex and span countries and continents. And it’s easy to feel removed from what’s happening on the ground.

But when it comes to categorizing suppliers into “buckets” based on their performance, take a moment to consider the potential implications. Sure, automation and quantitative scoring are great, but it’s easy to fall into the trap of viewing suppliers simply as names and numbers. Remember that most of your suppliers want to meet your criteria, put effort into developing long-lasting relationships, and grab every opportunity to improve.

Platforms and technology, as fantastic as they are, have their place. But when it comes to handling your low sustainability performers, ask yourself some of the questions we’ve raised above and tackle the issues with a holistic outlook.

After all, we’re all human.

SupplyShift was acquired by Sphera in January 2024. This content originally appeared on the SupplyShift website and was slightly modified for sphera.com.