The long-awaited update to the U.S. OSHA Hazard Communication Standard is finally here. This blog will go through the changes, some issues in the published standard and important items for you to consider when evaluating your materials.

(Text that appears in italics comes directly from the updated OSHA rule.)

Implementation deadline

The question asked most often is regarding the implementation deadline. OSHA opted for a staggered approach, differentiating between substances and mixtures:

(1) Effective date. This section shall become effective July 19, 2024.

(2) Substances.

(i) Manufacturers, importers, and distributors, evaluating substances shall be in compliance with all modified provisions of this section no later than January 19, 2026.

(ii) For substances, all employers shall, as necessary, update any alternative workplace labeling used under paragraph (f)(6) of this section, update the hazard communication program required by paragraph (h)(1) of this section, and provide any additional employee training in accordance with paragraph (h)(3) of this section for newly identified physical hazard, or health hazards or other hazards covered under this section no later than July 20, 2026.

(3) Mixtures.

(i) Chemical manufacturers, importers, and distributors evaluating mixtures shall be in compliance with all modified provisions of this section no later than July 19, 2027.

(ii) For mixtures, all employers shall, as necessary, update any alternative workplace labeling used under paragraph (f)(6) of this section, update the hazard communication program required by paragraph (h)(1) of this section, and provide any additional employee training in accordance with paragraph (h)(3) of this section for newly identified physical hazards, health hazards, or other hazards covered under this section no later than January 19, 2028.

(4) Compliance. Between May 20, 2024, and the dates specified in paragraphs (j)(2) and (3) of this section, as applicable, chemical manufacturers, importers, distributors, and employers may comply with either this section or § 1910.1200 revised as of July 1, 2023, or both during the transition period.

U.N. GHS version update

The update mainly implements the 7th revision of U.N. GHS. However, OSHA did include some updates from revision 8. This does help to keep the U.S. and Canada aligned, but it could make the implementation of this a little more complex. Furthermore, the commentary associated with the regulation is interesting and useful in understanding OSHA’s reasoning for the update along with the rebuttal to concerns raised in the draft document.

Definitions

A couple of new definitions have been added for bulk shipment and combustible dust.

Bulk shipment means any hazardous chemical transported where the mode of transportation comprises the immediate container (i.e., contained in tanker truck, rail car, or intermodal container).

Combustible dust means finely divided solid particulates of a substance or mixture that pose a flash-fire hazard or explosion hazard when dispersed in air or other oxidizing media.

Regarding bulk shipment, there were comments recommending that this match the definition implemented under U.S. DOT. OSHA did not take this recommendation, as they intended to use this definition as an exception in (f)(5)(ii) for shipments that do not have immediate forms of packaging. This difference is noted here to create awareness that the term will need to be used in the context of the regulation it is being applied to.

Combustible dust was not defined in the previous version of the standard, as OSHA had intended to implement this separately. OSHA had originally planned to implement the U.N. version of the definition, however there were many questions around the terminology being used, so the definition was changed to be more specific about the hazards involved.

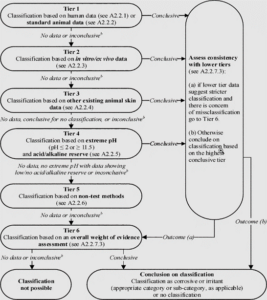

Hazard classification

An update was made to paragraph (d)(1) to clarify what should be considered when classifying a material. The Federal Register contains the following update:

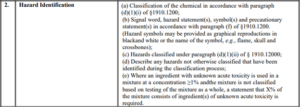

(d)(1)

(i) Chemical manufacturers and importers shall evaluate chemicals produced in their workplaces or imported by them to classify the chemicals in accordance with this section. For each chemical, the chemical manufacturer or importer shall determine the hazard classes, and where appropriate, the category of each class that apply to the chemical being classified. The hazard classification shall include any hazards associated with the chemical’s intrinsic properties including:

(A) A change in the chemical’s physical form and;

(B) chemical reaction products associated with known or reasonably anticipated uses or applications.

(ii) Employers are not required to classify chemicals unless they choose not to rely on the classification performed by the chemical manufacturer or importer for the chemical to satisfy this paragraph (d)(1).

OSHA stated that this was not meant to be a new requirement, but rather clarification of paragraph (b)(2), which states:

This section applies to any chemical which is known to be present in the workplace in such a manner that employees may be exposed under normal conditions of use or in a foreseeable emergency.

The commentary contained many discussion points around what this means and when a chemical reaction would need to be considered. OSHA was clear that they did not imply that that all possible chemical reactions should be considered. They gave the example of toluene, where it would not be possible to document all possible reactions that could occur. They were specific about it applying to anticipated uses. The examples they gave here indicated that they were talking about items such as kits where the hazards of the mixed kit ingredients might be different than those of the individual kit components. Other examples were specific use cases, such as hair straighteners giving off formaldehyde when exposed to heat. It will be important to keep these examples in mind when evaluating your own materials to determine the hazards associated with it.

In addition, OSHA specified that these types of hazards—those associated with a chemical reaction—were not required to be on the label. This is clearly stated in the commentary, but there does seem to be an error in the text of the Federal Register. Based on the context and examples given in the commentary sub-paragraphs, (A) and (B) (excerpted above) should have been (i) and (ii). Note that this was corrected in the red-lined version of the standard.