THE MINING & METALS INDUSTRY IS FACING UNPRECEDENTED DISRUPTION AND VOLATILITY

The impact of demographic changes on the workforce, rising stakeholder demands, tarnished reputations and increasing levels of EH&S performance needed to maintain license to operate are compounding the existing challenges of managing traditionally highly variable and uncertain mining and metals operations.

According to management consultant, McKinsey & Company, worldwide mining operations are as much as 28 percent less productive today than they were a decade ago.

Leading industry organizations are looking to achieve breakthrough performance by rethinking their operational and risk management strategies to make operations and maintenance safer, seamless and more efficient in terms of shift time and asset use.

WHAT IS YOUR OPERATIONAL RISK REALITY?

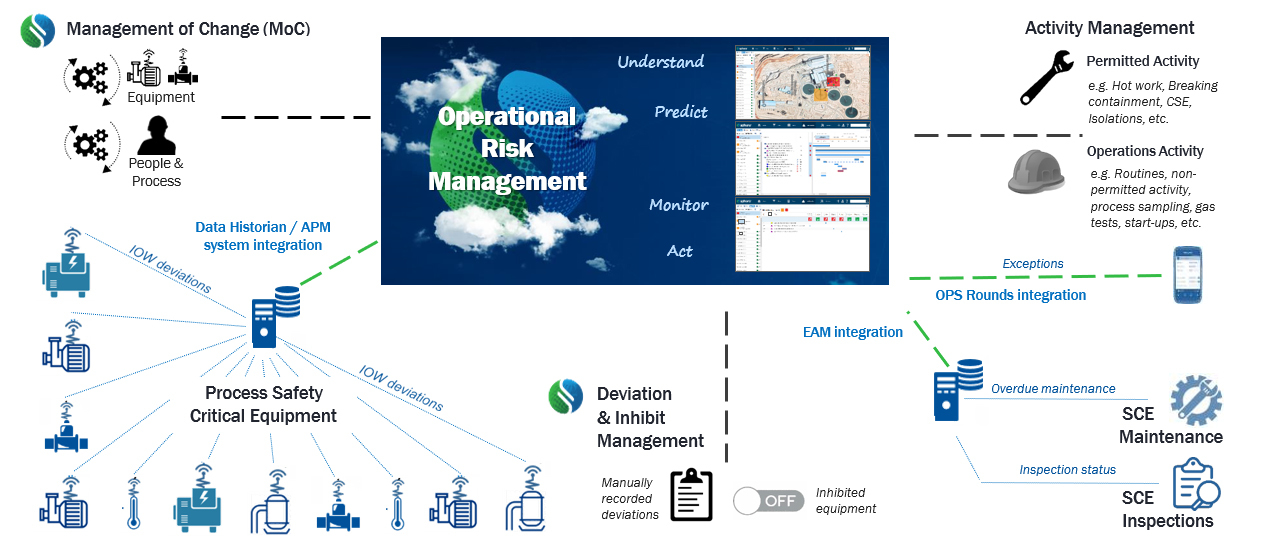

Since the day an asset becomes operational, or the last major hazard risk assessment (MHRA) was completed, its risk exposure began to change. And unavoidably, risks are often managed in different parts of the organization. Information is siloed. Dots are not connected.

Achieving breakthrough productivity performance requires organizations to rethink how mining operations work. It means reducing data silos, improving short interval control (SIC) with a visibility of all operational risks and activities, and enabling work teams to act decisively.