Whether on land or in the world’s oceans, plastic pollution is causing a global waste crisis. The problem is clear: Plastic production has grown exponentially, yet only a small fraction of plastic waste is ever recycled. This is associated with corresponding burdens on the environment. To address this issue, chemical recycling of plastics has emerged as a promising technology.

Unlike mechanical recycling, which involves melting and reforming plastic waste, chemical recycling breaks down the plastic at a molecular level. Furthermore, chemical recycling can handle contaminated and mixed plastics, which are difficult to recycle by traditional methods.

Sphera has joined the search for a solution. We regularly discuss the usefulness of the life cycle assessment (LCA) methodology, which evaluates the environmental impact of a product or process through its entire life cycle, from raw material extraction to disposal. In a whitepaper, we explain the need to harmonize approaches to life cycle assessment of chemical recycling technologies. And in an earlier blog, we explore the importance of closing the loop on chemical recycling.

Among Sphera’s most recent contributions to the field is a master’s thesis on LCA, “Analysis of Critical Modeling Aspects and Practical Implementation of a Life Cycle Assessment of the Chemical Recycling of Plastics”. This looks at the chemical recycling of post-consumer, mixed plastic waste through pyrolysis—heating in the absence of oxygen to break it down into smaller molecules—and related thermal technologies. The chemical recycling system was compared to current conventional plastic waste processing. The thesis was supervised by international experts in the field of LCA, Dr.-Ing. Martin Baitz of Sphera and Prof. Dr.-Ing. Jan Paul Lindner of University of Augsburg, Germany.

Key findings of the thesis are highlighted below. We also provide insight into how this work will benefit the overall LCA of chemical recycling through integration in Sphera’s Managed LCA Content (former GaBi Databases).

Assessing Recycling Methods and Generating LCA Data

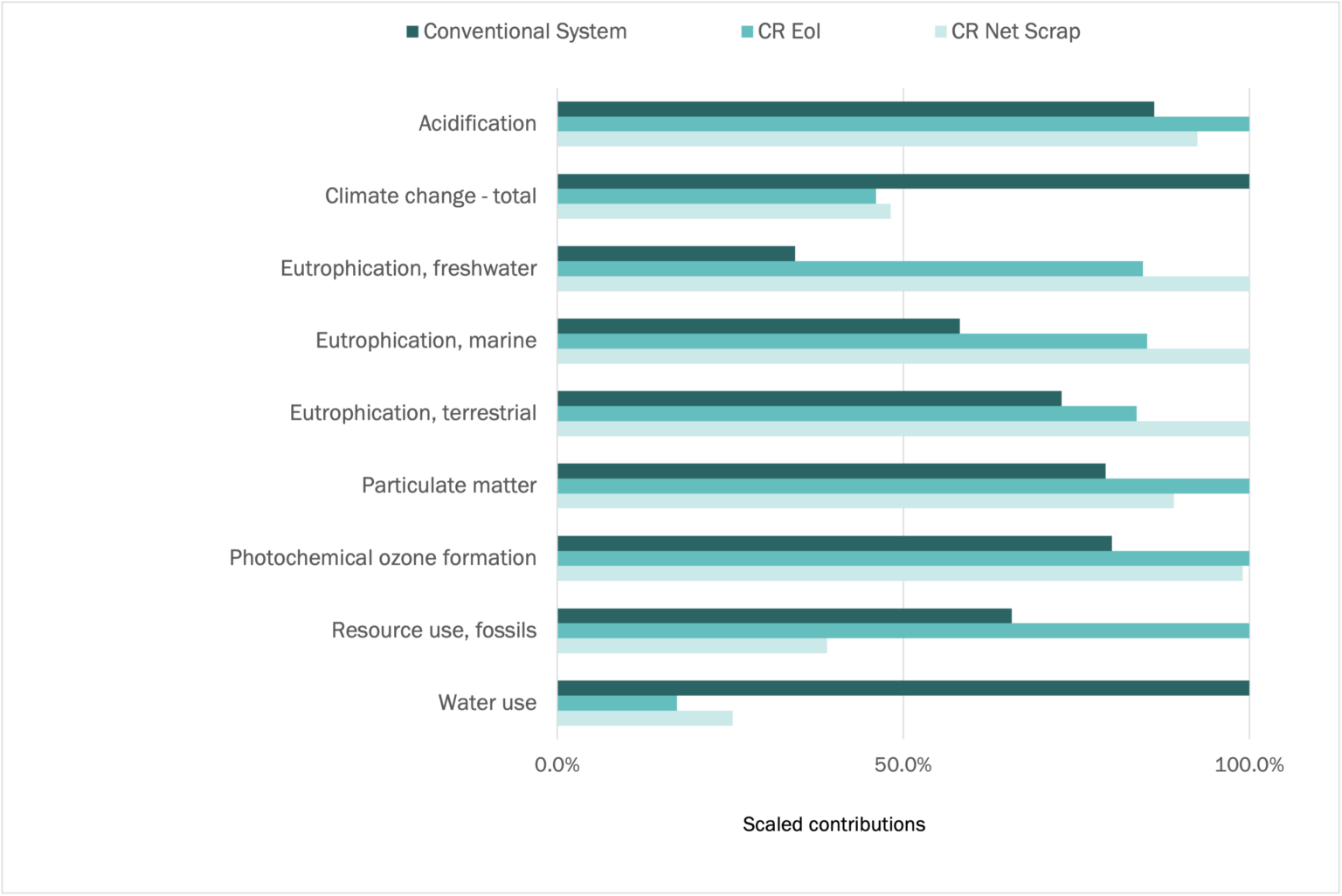

The thesis focuses on the environmental assessment of pyrolysis in Germany as part of the plastics value chain compared to conventional waste management methods and the virgin production of plastics from fossil resources. In addition, this thesis investigates the share of environmental burden on selected impact categories along the life cycle of chemical recycling. These impact categories include acidification, climate change, eutrophication, particulate matter, photochemical ozone formation, resource use and water use, among others.

The intended application of this thesis is twofold. First, it will generate datasets that can be included in Sphera’s Managed LCA Content (former GaBi Databases). Secondly, this investigation serves as a contribution to the discussion on the basic procedure for performing life cycle assessments for the chemical recycling of plastics. Overall, this thesis provides a wealth of data for stakeholders who deal with the topics of waste management, plastics production or the circular economy.

Understanding Environmental Impacts and the Potential for Technical Optimization

The first step to understanding environmental impacts and the potential for technical optimization is to identify the hotspots in chemical recycling of plastics. Here, the relative environmental burden of the sub-processes of chemical recycling on individual impact categories is important. These processes involve steam crackers, which “crack” hydrocarbon feedstocks into building blocks including ethylene, propylene, butadiene, aromatics and acetylene. Polymerization serves to chemically combine molecules (monomers) to produce large network molecules called polymers.

As illustrated by the following graph (Figure 1), pre-treatment has the lowest share across all impact categories (13.1% without weighting). The other sub-processes—pyrolysis (26.0%), steam cracker (30.4%) and polymerization (30.6%)—show higher values that are roughly similar.

Chemical Recycling: Significance of Sub-Processes in the Environmental Burden