Companies—particularly those in dangerous industries—rely on process safety management (PSM) and operational risk management (ORM) to keep their people safe, protect their business assets and prevent harm to surrounding communities and the environment.

Within these areas, activities and tools such as training, process control and safety-critical maintenance are used to achieve safety and security. But organizations operate in a dynamic environment. Threats, challenges and ways of working are always changing, and PSM and ORM must adapt as things change.

Every year since 2016, Sphera has surveyed hundreds of PSM and ORM professionals to find out how PSM and ORM are evolving and what’s driving successful process safety. Where do challenges lie, and how are companies addressing them?

In this year’s Process Safety Report—our 8th annual report—we learned that some findings have remained stubbornly consistent, particularly the gap between safety goals and reality. Yet other aspects, including respondents’ support for digital technology, continue to improve. Read on for three highlights from the report.

Understanding Safety-Critical Maintenance

Safety-critical maintenance is one of the most effective tools in the process safety toolbox. Yet survey participants report that one-third of scheduled safety-critical maintenance is not achieved in a typical month. What stands in the way of achieving 100% of safety-critical maintenance? Here are the top three challenges, according to this year’s survey respondents.

- Sixty percent of respondents say that limited resources present a problem. This figure is down from 74% in 2022. While it may indicate improvement in resource allocation, it is still significant among the challenges in achieving 100% of safety-critical maintenance.

- More than half of respondents (56%) cite conflicting priorities as a key challenge. One hypothesis is that organizations are listing too many tasks as safety-critical. Or opinions might differ as to what is critical, especially around what is critical for productivity versus what is safety-critical.

- Inadequate planning is named by 45% as a challenge to completing scheduled maintenance. This could reflect a lack of data integration. With paper-based systems, planners cannot combine information from multiple sources, including weather conditions or whether spare parts are available. So, they might not have the complete picture when scheduling tasks.

Implementing Digital Solutions

In 2023, all respondents believe that digitalization can enable effective process safety and operational risk management: 65% say it helps now and 35% think it will help in the future. The enthusiasm of PSM and ORM professionals for digital systems reinforces our conviction that the process safety gains made possible through digitalization cannot be emphasized enough.

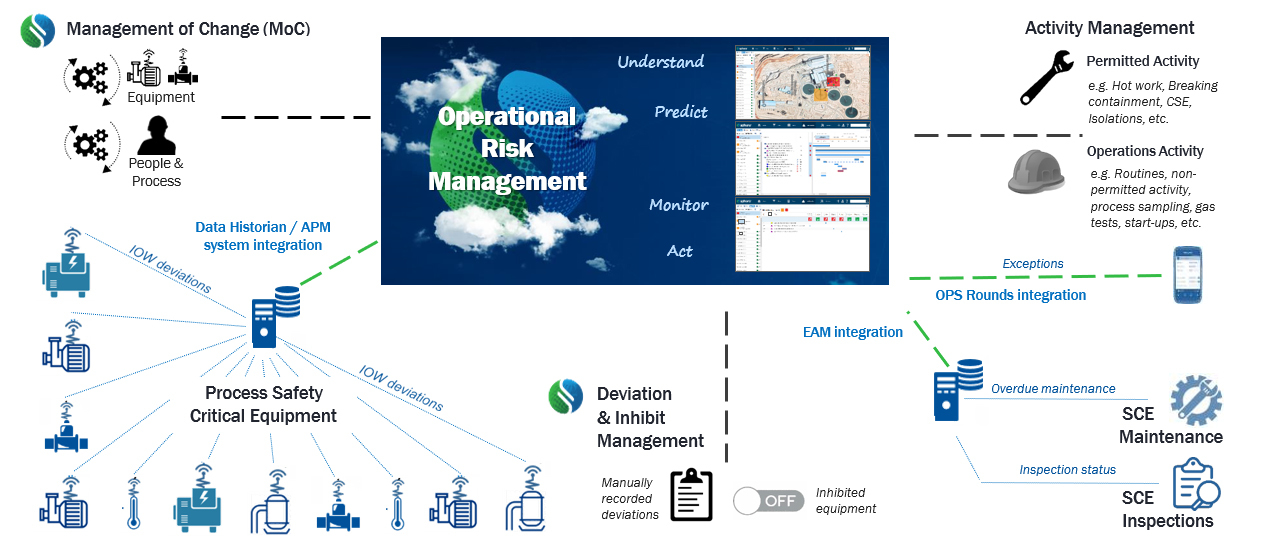

Digitalization enables companies to move from reactive to proactive process safety management, because digital systems work in so many different ways to promote safety. Whether risk assessments, permitting, control of work or simultaneous operations (SIMOPs), among other things, digital solutions make sure that all the correct steps are conducted in the right order.

For example, digital lists of pre-defined hazards, location-based hazards and controls are easy to access and search. Digital handoffs for permit ownership ensure that nothing gets misplaced or lost. Through integration of permits and controls, the correct procedures are standardized, thus advancing safety.

In general, it appears that hazardous industries are becoming more receptive to digital systems. External factors such as environmental, social and governance (ESG) requirements, economic conditions and supply chain impacts also drive acceptance. Our report provides information about the types of software solutions companies are using or plan to use to support safe operations.

Focusing on ESG Performance

Process safety management is important for a company’s ESG performance, according to 86% of respondents. Sixty percent believe PSM is important for their company’s environmental performance; 63% say it is relevant for governance; and 40% relate it to their company’s social performance.

Overall, a growing focus on ESG performance has elevated the role of effective PSM and ORM. In fact, 71% say incidents that have an environmental impact are highly concerning, which helps to illustrate the importance of PSM for ESG.

Although environmental impact has always been considered in risk assessments, an increasing focus from a broader set of stakeholders means that its criticality is higher than ever. By investing in their process safety management, organizations may be looking to improve their ESG performance.

Using digital tools, companies can report on process safety risk and performance faster and easier. They can integrate risk evaluation with other sources of information and across all levels. This advances their ability to keep people safe, while preventing harm to surrounding communities and the environment.

Ways to Reduce Risk and Improve Process Safety

In short, all respondents believe that digitalization can help reduce risk and improve process safety. Most organizations already use or plan to use digital solutions to support safe operations. Through such solutions, companies can embed, standardize and enforce best practices. This can ensure frontline adherence to policy and provide a repository for lessons learned, which is particularly important as experienced personnel leave the company or industry.

Many factors can impact the effectiveness of process safety management—both positively and negatively. To learn more about them and gain additional insights from our annual process safety survey, download the full Process Safety Report 2023 today.