The ever-increasing pressure on businesses to improve sustainability has forced them to find ways to measure the environmental footprints of their products.

Companies use life cycle assessment (LCA) to understand the environmental impact of products during their entire life cycle, from production and distribution to use and disposal.

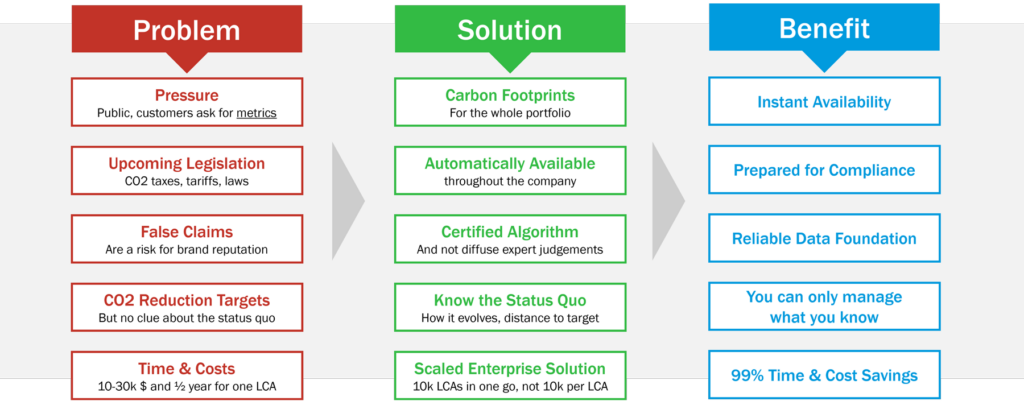

For many companies, performing LCAs for their entire product portfolio is no simple task. An internal expert or external consultant must collect data from fragmented systems, taking up to 12 months to complete an LCA for a single product. For a company with a portfolio of thousands of products, this process cannot easily scale. Realizing the limitations of the traditional LCA process, organizations often explore LCA automation, which uses technology to help them conduct LCAs at scale.

Stakeholders Demand Improved Sustainability

LCA automation has become popular as organizations field more requests for product information than ever before. They come from different audiences—from regulators and investors to consumers and internal corporate stakeholders. Businesses now have many compelling reasons to evaluate and improve their sustainability strategies:

- Increased regulatory intervention: Many governments have already imposed regulations on certain industries, but more directives are expected in the future. For example, in December 2021 the European Commission recommended a framework for calculating environmental performance. While still in a transition phase, the Product Environmental Footprint (PEF) and Organization Environmental Footprint (OEF) methods are expected to become mandatory in the coming years. When regulations like these come into effect, sustainability becomes a matter of compliance.

- Consumer and investor demand for sustainable products: Many investors believe that companies that have robust sustainability strategies perform better than their competitors that lack them. That may be due to consumer demand for sustainable products. In fact, a 2022 survey found that nearly 90% of Gen X consumers would be willing to spend an extra 10% or more for sustainable products.

- Corporate carbon-neutral and net-zero commitments: Company executives are under pressure to establish time-bound goals to achieve carbon neutrality and/or net zero. To achieve this, they must measure their current environmental performance and adapt their products or processes to make quantifiable improvements.

Companies Are Committed but Lacking Crucial Systems

Many of the world’s biggest consumer goods companies have set ambitious goals for reducing greenhouse gas (GHG) emissions, but few have systems in place to help them measure and manage these goals. Sphera recently conducted a survey of hundreds of companies that confirmed this: in 87% of organizations, senior management had committed to decarbonization goals, but only 26% of companies said they use a dedicated system to manage sustainability performance.

Adopting automated LCA technology can help companies at any stage of the sustainability journey. It is difficult for businesses to establish meaningful goals without first knowing where they stand. Consider one of the most complex sustainability metrics: Scope 3 emissions. Calculating Scope 3 emissions, which encompass all indirect emissions from a company’s value chain, is impractical without the aid of technology. LCA automation helps companies measure these emissions by looking at the full product life cycle.

Levels of LCA Automation

LCAs can be automated in various ways to suit different manufacturing processes and product types, helping organizations calculate LCAs at scale. Because companies within the same industries face similar challenges when calculating LCAs, some have begun to establish sector-wide standards.

Process manufacturing involves making similar products in similar ways (e.g., food and beverage products). LCAs in these industries contain predefined product variation parameters, and the values for these parameters can be imported from existing sources, such as recipes, to accelerate the process.

Discrete manufacturing entails the assembly of complex products composed of many parts (for example, computers or cars), resulting in a diverse portfolio of customizable products. As a result, hundreds of thousands of components must be tracked to calculate LCAs. Discrete manufacturers can automate this by importing product information from a Bill of Materials (BOM).

Chemical manufacturing often requires few materials but many steps in the manufacturing process—the complexity is in the production, not the product. To automate LCAs, chemical manufacturers need an abundance of primary data that covers every step in each product’s manufacturing process. This can be achieved through API integrations with other systems that the company uses to measure resource consumption, GHG emissions, waste and other metrics.