Permit to Work Software

Standardize your work practices for a safe and efficient environment.

Standardize your work practices for a safe and efficient environment.

Sphera’s Permit to Work software simplifies your entire workflow process. Everything is created, approved, processed, and communicated digitally and in real time. Sign-offs or approvals needed from other departments are communicated seamlessly and automatically, saving you valuable time.

Enable workers to follow procedures correctly, with information that’s accessible on the go. Workers can complete tasks by referring to the permit, and managers can see completed tasks in real-time.

Inspections, repairs and other maintenance and preventive activities are performed only after all safety measures – such as a LOTO process or safe confined space entry – are in place.

Sphera’s Permit to Work software combines real-time information from permits, isolations, hazards, maintenance shifts and SIMOPS. Managers can proactively schedule and coordinate throughout the entire facility, and dashboards offer a view of workers’ critical assignments.

This holistic view gives managers access to the right information at the right time to inform their operational decisions.

Sphera’s Permit to Work software helps organizations translate policy into consistent practice. Pre-defined templates – built on best practices for worker safety – encourage quick, accurate completion of projects. The solution also makes it easy to reinforce practices and policies as they evolve over time.

Benefit from purpose-built solutions with a seamless connection.

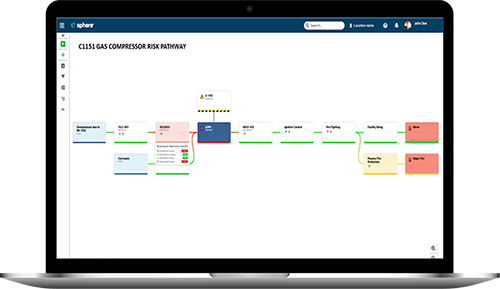

Sphera’s powerful Isolation Management helps protect from uncontrolled or unexpected releases of energy. It provides a framework and workflow-enabled processes for planning and creating safe work procedures to help deactivate energy sources, so maintenance work can begin.

Sphera’s Interactive P&ID streamlines isolation planning with quick access to engineering documentation and interactive capabilities to mark up piping and instrumentation diagrams.

Improve the management of interdependent risks with permitted and operational activities through visualization.

Gain insight before a shift, including what happened, current events and predictions for upcoming shift periods.

Efficiently manage contractors, ensure compliance with safety practices and reduce risk across the organization.

Learn more about how Sphera’s Control of Work system helps you take full control of your work activities and operational risk.