Simplifying Notifications to the ECHA SCIP Database

Starting Jan. 5, 2021, all companies supplying or importing products to the European Union markets that contain Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) Candidate List substances above 0.1% in any article must submit information about those substances to a newly established Substances of Concern In articles as such or in complex objects/Products, which is better known as the SCIP database.

The SCIP database is managed by the European Chemicals Agency (ECHA) and is a direct outcome from the 2018 revisions to the Waste Framework Directive. The aim is to promote the substitution of hazardous chemicals and provide waste operators with information about hazardous substances in the waste they process so that material streams can potentially be “cleaned” before recycling and reused in the production of new articles to ensure a true and safe circular economy.

Throughout summer, EU member states have been transposing the EU Waste Framework Directive requirements on SCIP database disclosure into national requirements. One example is in Estonia, which amended its Waste Act to include SCIP reporting in July.

The prototype SCIP database was launched in February 2020, and the live SCIP database will be available for companies to begin entering data in October 2020. Combined with Sphera’s BOMcheck supply chain tracking database, the S2S service allows companies to submit thousands of notifications at once.

Sphera’s BOMcheck blockchain web database is an official member of the ECHA IT User Group and has led industry discussions about the design of the database and how ECHA can develop technical solutions to simplify companies’ notifications to the SCIP database, including the system-to-system integrated submission service. BOMcheck was the first organization to launch a system-to-system integration to the SCIP database, and Sphera presented BOMcheck to the ECHA IT User Group in September.

Sphera’s Take

To help companies collect the necessary SCIP information from their supply chains, JB Hollister of Apple and I have led the development of the new IPC-1752B supply chain data exchange standard, which was published July 1. This new industry standard is applicable to products across all industry sectors and helps companies that want to collect data from their supply chains in a format matching the data requirements of the SCIP database. The standard exchanges data in XML which is the same format used by the SCIP database. It can be used to collect the SCIP numbers for supplier parts in IPC-1752B XML files, so that the BOMcheck supply chain tracking software can enable companies to reuse their suppliers’ submissions when making submissions for their products.

System-to-System Integration

The first technical solution that ECHA has developed to simplify the notifications duty for companies is to provide a system-to-system integrated submission service. Companies can use the service to prepare and submit a SCIP notification dossier automatically. Combined with Sphera’s BOMcheck supply chain tracking database, the S2S service allows companies to submit thousands of notifications at once. The BOMcheck supply chain tracking database matches the data requirements of the SCIP database and manages the connections to the SCIP database on behalf of the member companies.

Parent Company Submission

Another technical solution that ECHA provides is the “foreign user” feature. This allows one company to submit data on behalf of another company on a voluntary or contractual basis under the legal responsibility of the submitting company. This solution is useful for companies within a corporate group where the parent company wishes to submit data on behalf of its daughter companies, and for voluntary arrangements between companies. An example is a brand owner who might submit on behalf of a full, and closely controlled, supply chain.

The BOMcheck supply chain tracking software leverages this solution to enable the parent company to share their products’ dossiers directly with all companies within a corporate group, and for all companies in the group to automatically submit the same products’ dossiers to the SCIP database. BOMcheck can automatically update submissions on behalf of all companies in the group when suppliers update information for supplier parts for particular products.

Reusing Supplier Submissions

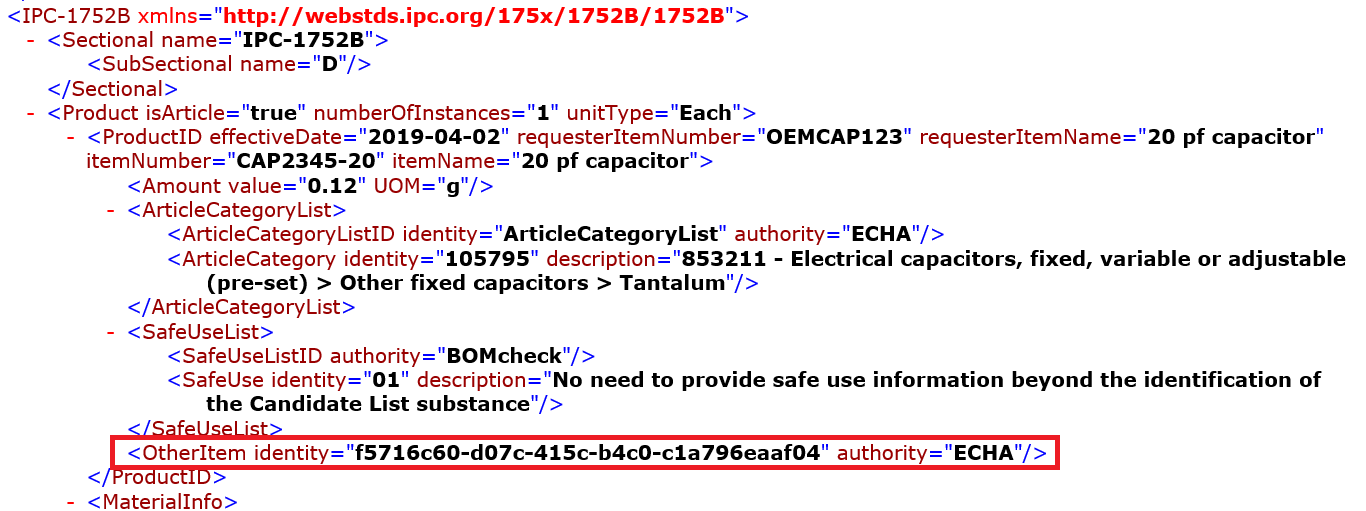

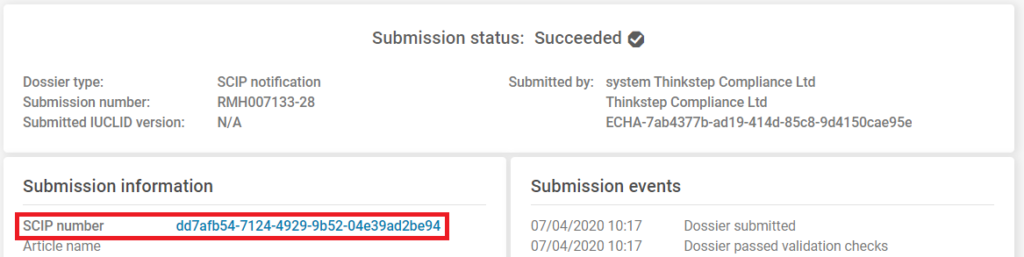

ECHA has also developed technical solutions to enable companies to reuse submissions made by their suppliers. As highlighted in Figure 1, each supplier part is allocated a SCIP number at the time of their first submission. The SCIP number is a random sequence of 36 hexadecimal characters that follows the Universally Unique Identifier (UUID) format. There is no relationship between the SCIP number for one supplier part and another part submitted by the same supplier.

Figure 1

The BOMcheck supply chain tracking software can capture the SCIP numbers for supplier parts and include them in companies’ submissions for their products. Without this solution, a company would need to create duplicate article submissions for supplier parts in their products that contain REACH candidate list substances.

To date, many companies have been focused on asking their suppliers to report whether the part contains a REACH candidate list substance above 0.1% in any article. In order to create duplicate article submissions for supplier parts in their products, these companies would also need to report the correct article category as well as the material category for each supplier part and the correct safe use information for the supplier part. Many companies would prefer not to take on the obligation of reporting information on behalf of their suppliers and will appreciate the opportunity to reuse their suppliers’ submissions instead.

Reusing submissions from suppliers will also help distributors. The BOMcheck supply chain tracking software can map distributors’ parts numbers to the suppliers’ part numbers and use the SCIP submission numbers to make a simplified notification to the ECHA SCIP database on behalf of the distributor. When the supplier updates their information, the distributors’ submissions are automatically updated.

Commentary From Verdantix

Independent research firm Verdantix spotlighted the BOMcheck blockchain web database for compliance to ECHA SCIP reporting requirements in their report published Aug. 14 titled, “Strategic Focus: Engaging the Value Chain on Product Stewardship.”

The Verdantix report highlights Siemens Healthineers and Ikea as two examples of large, multinational firms that use BOMcheck as a collaborative platform to maintain materials compliance declarations as well as provide regulatory training and chemicals guidance to suppliers and subsuppliers, and to phase out or substitute the REACH Candidate List Substances of Very High Concern in their supply chains and to contribute to a more sustainable and circular economy. In addition to maintaining compliance, Ikea’s Product Stewardship efforts are also driven by:

1. Grouping substances and minimizing or substituting use of regrettable chemicals.

2. Streamlining chemical regulations and reporting requirements.

3. Aligning with circular economy and climate policy initiatives. In fact, the World Economic Forum cites the “Circular Economy and Material Value Chains” as having the potential to yield up to $4.5 trillion in economic benefits by 2030.